234-Calibration of Granular Applicators for Herbicide Impregnated Fertilizer Applications

Fact Sheet No. 234, UMaine Extension No. 2434

Prepared by David E. Yarborough, Extension Blueberry Specialist, The University of Maine, Orono 04469. Revised February 2008.

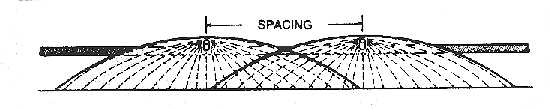

The amount of granules applied per unit of area depends on the size of the adjustable opening, the speed at which the equipment travels (or the speed of the hopper agitator), the roughness of the surface of the application site, and the granular formulation chosen. To determine the swath width, measure the actual swath on a hard surface. The effective swath of a spreader is difficult to determine because the rate per unit of area diminishes near the edge of the pattern. The effective swath probably wouldn’t exceed 75 percent of the greatest distance between granules. If the greatest distance between where granules landed to each side of the spreader was 40 feet, the effective swath should be in the 0.75 x 40 = 30 foot range. Because poor application occurs without adequate overlap, you should apply a 50 percent overlap for herbicide impregnated fertilizer. For example, if your total application width is 40 feet, then apply at a 20-foot spread but use one-half the application rate since you will be covering the area twice.

Because so many variables can affect the delivery rate, calibrate your equipment for each batch of product and for each new field condition.

First, run a pre-calibration check on the equipment:

- Fill the spreader hopper to a predetermined height or weight. Settle the material by driving a short distance or by shaking or striking the hopper; then refill the hopper.

- Set the flow rate as recommended by the equipment manual. The PTO rpm should be 540 and tractor speed should not exceed 2 mph.

- Turn on the spreader and operate on a hard surface to check for uniform distribution along the swath width. If you cover the surface with a tarp before making the test run, you can collect the granules for reuse.

- Next, operate the equipment over a measured area to determine whether the equipment is metering granules at the rate per acre you need.

- Calibrate your equipment using the method described below. The application rate per acre (or other unit area) depends on both the metered opening and the equipment speed. Minor adjustments in flow rates can be made by altering the rate of speed. (Faster speed means fewer granules delivered per area). Make larger adjustments by altering the equipment settings. If the application rate differs more than plus or minus 5 percent from the desired rate, adjust the equipment and recalibrate.

Calibration

- Mark off at least 100 feet in the field you wish to treat. A longer track length will provide a more accurate reading.

- Collect the granules discharged from one tube or opening during the 1,000-foot test run. If the equipment is motorized, bring it up to the speed you have selected before beginning the test run.

or

- Make the test run at the speed you have selected, but do not operate the applicator. Note the time (in seconds) it takes to complete the test run. Then with the equipment standing still, collect the granules discharged for that measured time.

To calculate the rate of application:

- Swath width X distance in test run (in ft.) / Square feet in an acre (43,560) = Area (in acres) treated in test run.

- Pounds used in test run /Area (in acres) treated in test run = Pounds per acre.

Example: To apply 200 lb/a DAP/Velpar calibrate for 100 lb/a

For DAP/Velpar application, use swath width = 20 feet.

- Test run = 100 feet DAP/Velpar.

- Amount used in test run = 4.5 pounds DAP/Velpar.

- Amount needed per acre = 100 pounds DAP/Velpar.

- Swath width (20 ft.) test run (100 ft.) / 43,560 sq. ft. = Area treated (0.0456 acre).

- Pounds in test run (4.5) / Area treated (0.0456) =Pounds per acre.

(4.5) / (0.0456) = 98 pounds per acre DAP/Velpar.

This is within plus or minus five percent of the specified rate of 100 lb/a DAP/Velpar, so the equipment is correctly calibrated.

If less than the specified weight, decrease tractor speed or increase spreader opening size. If more than specified weight, then increase tractor speed or decrease spreader opening size.

Precautions

When turning, be sure to turn off the spreader not just the PTO, since this will result in the tube filling while turning and a large amount of herbicide impregnated fertilizer will be applied to a small area. Crescent-shaped areas of blueberry leaf defoliation have been observed when just the PTO was turned off when turning.

Note: The use of herbicide impregnated on fertilizer is allowed by a herbicide 2ee label. Check the current Weed Control Guide for Wild Blueberries (#239) fact sheet for a listing of allowed herbicides and obtain the proper label prior to application of the herbicide fertilizer mixture.

Information in this publication is provided purely for educational purposes. No responsibility is assumed for any problems associated with the use of products or services mentioned. No endorsement of products or companies is intended, nor is criticism of unnamed products or companies implied.

© 2008

Call 800.287.0274 (in Maine), or 207.581.3188, for information on publications and program offerings from University of Maine Cooperative Extension, or visit extension.umaine.edu.

The University of Maine is an EEO/AA employer, and does not discriminate on the grounds of race, color, religion, sex, sexual orientation, transgender status, gender expression, national origin, citizenship status, age, disability, genetic information or veteran’s status in employment, education, and all other programs and activities. The following person has been designated to handle inquiries regarding non-discrimination policies: Director of Equal Opportunity, 101 Boudreau Hall, University of Maine, Orono, ME 04469-5754, 207.581.1226, TTY 711 (Maine Relay System).