Bulletin #7231, What We Have Learned About Heating With Wood Pellets in Maine

By Donna R. Coffin, Extension Professor, University of Maine Cooperative Extension.

For information about UMaine Extension programs and resources, visit extension.umaine.edu.

Find more of our publications and books at extension.umaine.edu/publications/.

Table of Contents

- Wood Is Regaining Importance in Maine Home Heating

- Wood Pellets and the Carbon Question

- Wood Pellets: What Are They?

- Areas of Concern Regarding Wood Pellets and the Burning of Pellets

- What Do Pellet Burners Think?

- Not All Wood Pellets Are the Same

- Costs: Comparing Wood Pellets to Other Heating Fuels

- Pellet Stove Maintenance

- Storing Pellets

- Chimneys / Venting

- Wood Burning and Air Quality Issues

Maine’s forests have long supported a variety of natural-resource-based industries, from providing ship masts for the king of England, to providing pulp for the paper industry. The production and use of wood pellets supports Maine’s forest industry and continues Maine’s tradition of managing and utilizing our forest resources to support Maine people.

Wood Is Regaining Importance in Maine Home Heating

In Maine, wood was our primary source of home heating fuel before the 1950s. Its importance decreased as more convenient alternatives, such as fuel oil, were found, but when fuel oil prices skyrocketed in the 1970s, the use of wood heat grew from 2% to 15% of households. Yet the 2000 census showed that only 6% of Maine homes used wood as their primary source of heat, and 80% of Maine households relied on No. 2 fuel oil.1

In Maine, wood was our primary source of home heating fuel before the 1950s. Its importance decreased as more convenient alternatives, such as fuel oil, were found, but when fuel oil prices skyrocketed in the 1970s, the use of wood heat grew from 2% to 15% of households. Yet the 2000 census showed that only 6% of Maine homes used wood as their primary source of heat, and 80% of Maine households relied on No. 2 fuel oil.1

However, in a Maine Residential Heating and Energy Survey conducted in the winter of 2008, half of the people participating in the survey said they planned to use wood heat as their primary or secondary source of heat.2 Many of the survey respondents indicated that they planned to use wood pellet stoves—a newer and more efficient technology than traditional wood stoves.

Increasing crude-oil costs have brought new attention to Maine’s reliance on outside sources of energy to heat homes. Much crude oil comes from other countries, with the United States relying heavily on outside sources to meet our energy needs. The April 2010 Deepwater Horizon oil spill in the Gulf of Mexico has highlighted the vulnerability of tapping into domestic off-shore oil reserves.

Wood Pellets and the Carbon Question

A growing concern for the environment, including a desire to limit carbon dioxide emissions, has brought new interest to the use of wood for energy. When compared to oil, wood emits carbon dioxide at the rate of 7 kg/million BTUs,3 while oil emits 79 kg/million BTUs.4 A study from the Manomet Center for Conservation Sciences speculated that the burning of biomass, including wood pellets, would result in a “carbon debt,” meaning a net increase in greenhouse gases. However, the study concluded that these excess emissions could be offset by forest growth over time and could result in a “carbon credit.” This carbon amount varies according to the type of fuel the biomass is replacing. The study estimated that the carbon debt payoff would be five years for burning wood as an oil replacement for thermal energy.5

Dr. Robert Rice of the University of Maine School of Forest Resources states that the carbon dioxide released from the combustion or decay of woody biomass is part of the global cycle of biogenic carbon and does not increase the amount of carbon in circulation.6 In contrast, carbon dioxide released from fossil fuels increases the amount of carbon in circulation, or increases the “carbon debt.”

Rice goes on to say that while there is no difference between the greenhouse gas properties of biogenic and fossil carbon dioxide, they differ in terms of where the carbon is sourced. Burning fossil fuels that are mined from millennia-old deposits of carbon produces an addition of carbon in the atmosphere, whereas burning woody biomass recycles renewable plant growth in a sustainable carbon equilibrium, producing carbon-neutral energy. Fossil fuels also produce other greenhouse gases and pollutants with more negative environmental impacts than woody biomass.7

To be considered “absolutely carbon neutral,” biomass must be regrown at the same rate at which it is consumed. Sustainable forestry practices can help ensure that biomass is replaced at the same rate it is removed.

Our forests are our nation’s primary source of renewable materials and second largest source of renewable energy after hydropower. Sustainable development of new and traditional uses of our forests helps reduce greenhouse gas emissions,8 and provides economic incentives to keep lands in forests, reducing the motivation for land conversion.

Wood Pellets: What Are They?

Wood pellets are made from compacted sawdust and woodchips. These are byproducts from sawmills and other industries that use wood. The pellets are formed under heat and pressure, which releases natural plant lignin that holds the pellets together without glue or additives.

Wood pellets are made from compacted sawdust and woodchips. These are byproducts from sawmills and other industries that use wood. The pellets are formed under heat and pressure, which releases natural plant lignin that holds the pellets together without glue or additives.

Currently there are four wood pellet manufacturers in Maine, with several other manufacturers shipping in pellets from other states and Canada.9 Maine pellet manufacturers have increased their pellet production by 50%, in response to market demands that created a shortage of wood pellets in the fall of 2008.

In 2008, a Maine Forest Service analysis estimated conservatively that an additional 4 million green tons of low-grade wood could be harvested each year from Maine’s forests without affecting other forest values such as water quality and biodiversity. Roughly half of this total is estimated to be suitable for the production of wood pellets. Forest Service officials believe that there is an adequate supply of low-grade wood, both in Maine and in surrounding states and provinces, to ensure continued opportunities for Maine’s existing forest industry as well as for new ventures.10

Areas of Concern Regarding Wood Pellets and the Burning of Pellets

- Unless a hopper system is installed, someone in the household needs to be able to carry 40-pound bags of pellets into the home to fill the pellet-burning appliance.

- Daily ash-cleanout maintenance can pose an unexpected daily duty not associated with oil, propane, or electric heat.

- As with any wood-burning appliance, some of the products of combustion are corrosive enough to cause interior stove parts to deteriorate, leading to unexpected costly repairs.

- Wood pellets that are stored outside can pick up a lot of moisture. Since this moisture must evaporate before heat can be released to heat the home, this can result in a loss of up to one-third of the potential heat in the pellets.

- There have been newspaper accounts of pellet stove operators experiencing variable amounts of heat from different bags of pellets.11 This poses the question of how variable the heating quality of wood pellets is, between batches of pellets from one manufacturer, as well as between manufacturers. It also highlights the importance of how pellets are stored.

What Do Pellet Burners Think?

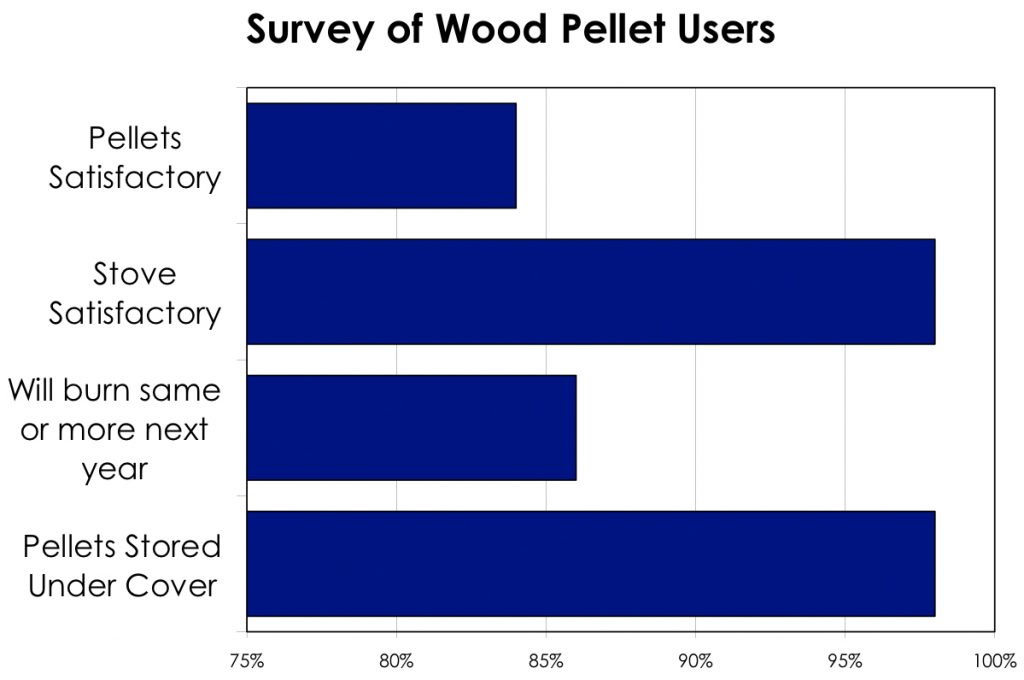

In a 2010 survey (conducted by University of Maine Cooperative Extension) of 45 wood-pellet users, 28 (62%) respondents had burned wood pellets for between two and four years, and 11 (24%) had burned pellets for more than five years. Of those responding, 84% were satisfied with the wood pellets that they’d burned the previous year, while 98% were satisfied with their wood-pellet-burning appliance/system. When asked about their plans for burning wood pellets the next heating season, 32 people, or 71%, planned to burn the same amount of pellets; 7 people, or 15%, planned to burn more pellets; and 6 people, or 13%, planned to burn fewer pellets.

In a 2010 survey (conducted by University of Maine Cooperative Extension) of 45 wood-pellet users, 28 (62%) respondents had burned wood pellets for between two and four years, and 11 (24%) had burned pellets for more than five years. Of those responding, 84% were satisfied with the wood pellets that they’d burned the previous year, while 98% were satisfied with their wood-pellet-burning appliance/system. When asked about their plans for burning wood pellets the next heating season, 32 people, or 71%, planned to burn the same amount of pellets; 7 people, or 15%, planned to burn more pellets; and 6 people, or 13%, planned to burn fewer pellets.

Twenty-two respondents (48%) indicated that they buy their pellets once a year, while six (13%) buy pellets once or more a month. The most common price paid was from $250 to $300 per ton, excluding delivery cost. Eighteen people (40%) purchased more than three tons of pellets last year and another eighteen (40%) purchased between two and three tons a year. About half of the people (51%) said they store their pellets outside in a cool, covered area (unheated garage, shed, etc.), and 47% said they store their pellets in a warm part of the house (basement, heated garage, etc.)

Fifty-nine percent indicated that they have had some or a lot of problems with pellets leaving more ash than they expected, particularly when burning poorer quality pellets, and 53% experienced some or a lot of problems with the pellets falling apart into sawdust. Other issues included clinkers (lumps of ash and unburned wood residue), pellets getting caught in the auger, and pellets burning too fast.

Not All Wood Pellets Are the Same

Wood pellets can vary by species of wood, amount of moisture, amount of dirt, size, how well they hold together, and other variables. They may be composed of sawdust, tree bark, paper, and/or cardboard, depending on grade. These can all affect the quality of the pellet as well as the ease of use and heating ability.

How much variation in heat value (content) or energy density (expressed as British Thermal Units/BTUs) per ton occurs in pellets, within the manufacturer on a seasonal basis, between manufacturers, and between vendors selling directly to consumers?

There are no uniform criteria assessing the quality of pellets that would allow consumers to determine the relative energy value of wood pellets from various manufacturers. Wood pellet manufacturers are trying to develop criteria for different grades of wood pellets, but have not assigned a heating value or energy density to the different grades.12

The Pellet Fuels Institute (PFI), a North American trade organization, has defined four grade standards: PFI Super Premium, PFI Premium, PFI Standard, and PFI Utility. They differ primarily in the percentage of inorganic ash content.

| Fuel Property | PFI Super Premium | PFI Premium | PFI Standard | PFI Utility |

|---|---|---|---|---|

| Bulk Density, lb/cubic foot | 40–46 | 40–46 | 38–46 | 38–46 |

| Inorganic Ash % | ≤ 0.50 | ≤ 1.00 | ≤ 2.00 | ≤ 6.00 |

| Moisture % | ≤ 6.0 | ≤ 8.0 | ≤ 8.0 | ≤ 10.0 |

While grading criteria do not include a value or range for heating value, the organization does require participating manufacturers to do independent testing for heating value and list their pellets’ mean value on their bags.

The Analytical Laboratory at the University of Maine has been testing pellets from a number of manufacturers from different seasons. Ash values ranged from 0.4% to 1.1%. They found that the moisture level at the plant is about 6%. An open bag of pellets left outside can have a moisture level of 12%. Unopened bags of pellets stored on a concrete slab will experience increased levels of moisture—up to 20%—in the pellets closest to the slab. At this level, mold can start to grow and cause air quality problems in the home. Placing bags on pallets to get them off the floor will alleviate this problem.

Why worry about moisture level of pellets? A bag of pellets at 6% moisture will weigh forty pounds and has 400,000 BTUs of energy. If that same bag becomes damp and develops a moisture level of 20%, it will weigh almost 50 pounds but will only have about 270,000 BTUs of energy, because the water must be vaporized before heat can be released. You lose a third of your heating potential and have to lug in a bag that weighs 25% more!

Costs: Comparing Wood Pellets to Other Heating Fuels

In general, there are three reasons consumers have gone to wood pellets for their home heating needs: (1) pellet-burning costs less than oil; (2) it is more convenient than stick wood; and (3) it reduces the consumer’s carbon footprint.

To calculate the cost to heat our homes with various fuels, we convert the costs to cost per million British Thermal Units (mBTU). All of the non-wood-derived fuels have been tested and rated for BTU content. Depending on the source, the average numbers can vary. But for our purposes we can use the numbers below.

| Estimated Energy Content of Various Fuels | ||

|---|---|---|

| Unit | BTUs /unit | |

| Wood pellets | Pound | 8,000 |

| Hardwood logs | Cord | 24,000,000 |

| Fuel Oil (No.2) | Gallons | 135,000 |

| Natural Gas | Therm | 100,000 |

| Propane | Gallons | 92,500 |

| Electricity | Kwh | 3,413 |

The Heating Fuel Cost Equivalence chart below allows us to easily compare the cost per million BTUs among wood pellets, hardwood, fuel oil, natural gas, propane, and electricity.

Consideration is given to the efficiency of the heating appliances. Annual Fuel Utilization Efficiency (AFUE), expressed as a percentage, is a measure of how efficiently a heating appliance turns heat released from burning fuel into heat you can use to warm your home. Heat is lost through incomplete combustion of fuel and heat going up the chimney. Wood pellet stoves average 80% to 85% overall efficiency.13

Pellet stoves are eight to ten times more efficient than fireplaces, up to three times more efficient than wood stoves, and similar in efficiency to natural gas furnaces. Pellet stoves create very little creosote buildup, drastically reducing the chance of a chimney fire and the need for frequent chimney cleanings. Built-in heat shields protect against accidental burns and allow pellet stoves to be placed closer to walls.14

| Heating Fuel Cost Equivalence* | |||||||

|---|---|---|---|---|---|---|---|

| Type of Fuel | Wood Pellets | Hardwood | Fuel Oil | Natural Gas | Propane | Electricity | |

| Unit | Ton | Cord | Gallon | Therm | Gallon | Kwh | |

| Heating system efficiency (AFUE) | 80% | 70% (catalytic stove) |

85% | 95% | 95% | 100% | Cost per million BTU: |

| Price per unit | $205 | $269 | $1.88 | $1.52 | $1.41 | $0.05 | $16 |

| $230 | $302 | $2.12 | $1.71 | $1.58 | $0.06 | $18 | |

| $256 | $336 | $2.35 | $1.90 | $1.76 | $0.07 | $20 | |

| $282 | $370 | $2.59 | $2.09 | $1.93 | $0.08 | $22 | |

| $307 | $403 | $2.83 | $2.28 | $2.11 | $0.08 | $24 | |

| $333 | $437 | $3.06 | $2.47 | $2.28 | $0.09 | $26 | |

| $358 | $470 | $3.30 | $2.66 | $2.46 | $0.10 | $28 | |

| $384 | $504 | $3.53 | $2.85 | $2.64 | $0.10 | $30 | |

*Derived from the Heating Fuel Equivalence Chart in University of Maine Cooperative Extension bulletin #7216, “How Much Heat per Dollar?”15

You can calculate your fuel cost per million Btu using this equation:

![[(Cost of the fuel) multiplied by (1 million BTU)] divided by (BTU per unit of fuel) divided by AFUE of the heating appliance](https://extension.umaine.edu/publications/wp-content/uploads/sites/52/2013/11/equation.jpg)

Multiply the unit cost of the fuel by 1 million BTU. Divide the result by the amount of BTU per unit of fuel. Then divide once again, this time by the AFUE of the heating appliance.

For example:

- Unit cost of wood pellets = $282 per ton

- Heat value of wood pellets = 16,000,000 BTU

- AFUE of heating appliance = 80%

Put the numbers into the formula:

[(282 x 1,000,000)] = 282,000,000 / 16,000,000 = 17.6 / 0.80 = $22 per mBTU

What does this mean? If you pay $307 per ton for wood pellets, it would cost the same as paying $2.83 per gallon of fuel oil to heat your home. Hardwood firewood remains a bargain, since even if you paid as much as $403 a cord, your cost for the heat (per mBTU) would be equivalent to paying $2.83 per gallon of fuel oil. In the fall of 2013, wood pellets are ranging from $250 to $300 per ton, which is equivalent to paying from $2.35 to $2.80 per gallon of oil.

Of course there is a lot of labor and maintenance involved in splitting and stacking wood, stoking the stove, removing ash, etc. Although pellet-burning stoves still require a number of maintenance practices that need to be performed on a daily, weekly, or monthly basis, wood pellets offer a more convenient method of burning wood.

Future sources for biomass pellets being investigated include hay, grain, and grass/broad-leafed plants. Energy density criteria could also help consumers in understanding the relative value of these biomass pellets.

Pellet Stove Maintenance

While there are regular maintenance tasks necessary to assure the clean, safe, efficient use of a wood pellet stove, pellet stoves take a lot of the hard work and inconvenience out of burning wood. Wood pellets come in 40-pound plastic bags that can be carried into the house without the mess of stick wood. Pellet stoves need to be filled regularly, but once a day is generally sufficient during the heating season.

While there are regular maintenance tasks necessary to assure the clean, safe, efficient use of a wood pellet stove, pellet stoves take a lot of the hard work and inconvenience out of burning wood. Wood pellets come in 40-pound plastic bags that can be carried into the house without the mess of stick wood. Pellet stoves need to be filled regularly, but once a day is generally sufficient during the heating season.

Ash needs to be cleaned out of the stove at least weekly. Some stoves and/or pellets can necessitate more frequent cleanings. Monitor the auger system to be sure the pellets continue to flow to the combustion chamber.

A new generation of automatic-feed wood boilers has started to be manufactured. These systems include large storage bins that are placed in your basement, garage, or attached shed and filled by a bulk pellet delivery truck on a regular basis. While these systems cost more to install, they do eliminate the daily chore of carrying 40-pound bags to the pellet stove, boiler, or furnace. One note of caution: these stoves need regular cleaning to clear away ash and allow the system to work properly. Some newer automated boiler systems include an auger system to clear away ash for longer-term storage.

Yearly upkeep includes greasing augers, gear boxes, and other moving parts. Regular inspection for corrosion in the metal of the combustion chamber, as well as wear on conveyors, augers, or gear boxes, combined with timely parts replacement or repair, will keep the wood-burning appliance safe and efficient.

Storing Pellets

Fresh wood pellets from the manufacturer may have some residual moisture that needs to evaporate. Although the pellets may be packaged in plastic bags and wrapped in plastic on pallets, they should be stored under the protection of a roof and elevated off the ground or floor. Bags of pellets stored on the ground or cement slab will absorb moisture both through the plastic (which is perforated) and through condensation of moisture inside the bag. This excess moisture can lead to a breakdown of the pellets, reducing durability and heat-producing capacity. It can also lead to mold growth.

Automatic-feed wood pellet boilers include large top-load or bottom-unload bins, similar to grain bins found on farms. These are best placed in a heated basement. As more homes install this type of storage system, bulk distribution of wood pellets will become feasible, with delivery by truck once a month or as needed. Pellets would be transferred to the large storage bin in the basement or garage.

Chimneys / Venting

Most wood pellet stoves are so efficient that the flue gases are low enough in temperature to be exhausted through a direct vent or power vent through the side wall of the basement or house. It is very important to follow the manufacturer’s installation and use instructions when installing and using a wood pellet stove.

Occasionally wood pellet stoves with a direct vent through a wall may leave soot marks on the siding of the building. This is from incomplete burning of the pellets, which can occur when the stove is being stoked or the ash bin is being cleaned. Follow manufacturer’s directions when doing these operations. Also, soot can occur when other materials are burned in the pellet stove. Burning household trash in a pellet stove can foul the auger and burner of the stove and is not recommended.

The U.S. Environmental Protection Agency’s Burnwise website provides information on woodstoves, including

- Clean-burning woodstoves,

- Healthy homes,

- Health effects of wood smoke,

- Cleaner burning fireplaces, and

- Tips for better fires.

Wood Burning and Air Quality Issues

Wood is a natural, renewable resource if harvested in a sustainable manner. However, the environmental benefits are canceled if people use inefficient wood-burning techniques and devices that give off high amounts of fine particles and toxins. Lower levels of pollution are given off when seasoned firewood is burned in a manner that promotes complete combustion. Small, hot fires are better than large smoldering fires. Wood pellet stoves, when used properly, burn wood more completely (efficiently) than most stick-wood burning stoves16. Pellet burners must still exercise care when opening the stove for servicing or cleaning, to ensure that wood smoke is not released into the house.

Special thanks to the following reviewers:

- Dr. Robert Rice, Professor of Wood Science, School of Forest Resources, University of Maine

- Dr. Dave Morrison, Assistant Professor Mechanical Engineering Technology, University of Maine

- Tim Vrabel, Strategic Initiatives Specialist, Efficiency Maine

- Andrew Plant, Assistant Extension Professor, University of Maine Cooperative Extension

- Kathy Hopkins, Extension Professor, University of Maine Cooperative Extension

1 United States Census Bureau, U.S. Department of Commerce, “Historical Census of Housing Tables: House Heating Fuel,” last modified October 31, 2011, http://www.census.gov/hhes/www/housing/census/historic/fuels.html

2 American Lung Association of Maine, “Maine Residential Heating and Energy Survey,” November 2008, accessed 11/09, http://www.docstoc.com/docs/44172162/Maine-Residential-Heating-and-Energy-Survey-Report-of-Findings

3 Georgia Forestry Commission, “Energy Balance of Wood Pellets,” 2011, http://www.gfc.state.ga.us/ForestMarketing/documents/EnergyBalanceofWoodPellets-Mar2011.pdf

4 Cox, A., “Low Carbon Heating with Wood Pellet Fuel,” 2003, retrieved October, 2013, http://www.nef.org.uk/logpile/pellets/documents/PelletReport.pdf

5 T. Walker, et al., Biomass Sustainability and Carbon Policy Study, Manomet Center for Conservation Sciences, 2010, https://www.manomet.org/sites/default/files/publications_and_tools/Manomet_Biomass_Report_Full_June2010.pdf

6 Rice, R., Written testimony to the Senate Environment and Public Works Committee, June 2010.

7 Rice testimony

8 Consortium for Research on Renewable Industrial Materials, “Maximizing Forest Contributions to Carbon Mitigation: The Science of Live Cycle Analysis – a Summary of CORRIM’s Research Findings,” CORRIM Fact Sheet #5, 2009, www.corrim.org/pubs/factsheets.asp

9 H. Spelter and D. Toth, North America’s Wood Pellet Sector, USDA Forest Service FPL-RP-656, 2009, http://www.fpl.fs.fed.us/documnts/fplrp/fpl_rp656.pdf

10 State of Maine Wood- to-Energy Initiative: Frequently Asked Questions, http://www.maine.gov/doc/initiatives/wood_to_energy/faq.html

11 K. LeBlanc, “My Day: The pellet stove generation,” Piscataquis Times – SV Weekly, Oct. 23, 2009.

12 Pellet Fuels Institute, “PFI Fuel Grade Requirements,” www.pelletheat.org, accessed November, 2009.

13 U.S. Department of Energy, Energy.Gov, “Energy Saver: Wood and Pellet Heating,” 2010, http://energy.gov/energysaver/articles/wood-and-pellet-heating

14 Wisconsin Focus on Energy, “Heating your home with wood pellets,” Renewable Energy Fact Sheet, 2002, www.focusonenergy.net/files/Document_Management_System/Renewables/heatinghomewithwoodpellets_factsheet.pdf.

15 Coffin, D., “Maine Home Energy: How Much Heat per Dollar?,” Bulletin #7216, 2008.

16 Maine Department of Environmental Protection, Bureau of Air Quality, “Reducing the Impacts of Woodsmoke,” http://www.maine.gov/dep/air/woodsmoke/documents/owboperpract.pdf

Information in this publication is provided purely for educational purposes. No responsibility is assumed for any problems associated with the use of products or services mentioned. No endorsement of products or companies is intended, nor is criticism of unnamed products or companies implied.

© 2013

Call 800.287.0274 (in Maine), or 207.581.3188, for information on publications and program offerings from University of Maine Cooperative Extension, or visit extension.umaine.edu.

The University of Maine is an EEO/AA employer, and does not discriminate on the grounds of race, color, religion, sex, sexual orientation, transgender status, gender expression, national origin, citizenship status, age, disability, genetic information or veteran’s status in employment, education, and all other programs and activities. The following person has been designated to handle inquiries regarding non-discrimination policies: Sarah E. Harebo, Director of Equal Opportunity, 101 North Stevens Hall, University of Maine, Orono, ME 04469-5754, 207.581.1226, TTY 711 (Maine Relay System).