Bulletin #4297, High-Pressure Processing of Vacuum-Packaged Scallops and Lobster Tails for Sous Vide Cooking

Developed by Jason Bolton, Assistant Extension Professor for Food Safety, University of Maine Cooperative Extension, Denise Skonberg, Associate Professor of Food Science and Human Nutrition, University of Maine, and Ph.D. students Sami Humaid and Dhriti Nayyar.

Table of Contents:

- Scallops and lobsters: Valuable, healthful, and delicate

- Purpose

- What is sous vide?

- What is HPP and why do we need it?

- General food safety concerns for vacuum-packed foods

- Overall objectives of our work

- Physical and chemical analyses and consumer acceptability testing

- Results

- Take-home messages

- References

Scallops and lobsters: Valuable, healthful, and delicate

Scallops and lobsters are some of the most valuable seafood consumed worldwide. They are prized for their healthful nutrient contents and unique flavor and texture. Scallops and lobsters are some of the most expensive menu items in restaurants. The most common ways to cook lobsters are boiling, steaming, or grilling. Scallops are typically pan-seared, baked, or grilled. However, conventional cooking methods increase the susceptibility to over-cooking seafood and can result in a tough, chewy, and rubbery mouthfeel. On the other hand, sous vide offers evenly and perfectly cooked scallops and lobsters with superior tender and juicy texture.

Seafood consists primarily of proteins and water. Proteins play an essential role in defining seafood texture such as tenderness and juiciness, but food processing methods may modify protein structures, affecting the texture of the meat.

Purpose

Sous vide products represent a growing trend in the food industry and among consumers. Applying high-pressure processing (HPP) to already vacuum-packaged seafood may offer extended refrigerated shelf life while maintaining their intrinsic quality. However, like any processing step, the application of HPP may affect the quality of the food. This bulletin highlights the changes that HPP brings in sensory and other quality properties to HPP-treated and sous vide–cooked scallops and lobster tails, as well as the effects of HPP on the refrigerated shelf life of raw scallops and lobster tails.

What is sous vide?

Sous vide, French for “under vacuum,” is the controlled, low-temperature cooking of vacuum-sealed foods in a water bath. During vacuum packaging, the air is removed from the package prior to sealing and the food is enclosed in an airtight, hermetically sealed package. Vacuum packaging, along with the precise temperature cooking of sous vide, allows more control of doneness and texture, and the resulting food is often considered of superior quality compared to conventionally cooked products. Sous vide is already a popular technique used in fine-dining restaurants and among innovative chefs. Many consumers are now trying their hand at sous vide cooking at home due to the availability of reasonably priced sous vide equipment (Figure 1).

Meat and seafood products are typically vacuum-packed with marinades and cooked for a specific duration and temperature, and are enjoyed for their flavor and texture (Figures 2a and 2b). Due to the circulating water bath providing uniform heating and the lack of air in the package, the muscle protein cooks evenly, giving the cooked meat a desirable texture. But sous vide is not just for meats. For example, Starbucks recently launched sous vide egg bites: egg whites that are sous vide–cooked to attain a velvety texture.

What is HPP and why do we need it?

The food industry uses HPP, a non-thermal process because it can control food-spoilage microorganisms, thus extending product shelf life. HPP is commonly applied to prepackaged food using select pressures (200–600 MPa), holding times (10–30 min), and temperatures (5–90°C), depending on the product and desired effects. The pressure generated is transmitted by a liquid medium, usually water, which is assumed to treat all parts of the food uniformly (Figures 3a and 3b).

Currently, prepackaged scallop/lobster products for on‐site sous vide cooking are not commercially available because of their short shelf life under refrigeration. Freezing can extend the shelf life of seafood, but that may come at significant cost to the quality benefits of sous vide cooking because ice crystal formation can negatively affect seafood texture. HPP has the potential to increase the shelf life while maintaining the quality properties of fresh, additive-free, minimally processed foods.

Using HPP as a pre-treatment for seafood ready to be sous vide–cooked may prove a promising tool to extend the shelf life of refrigerated seafood with minimal negative effects on its qualities.

General food safety concerns for vacuum-packed foods

Clostridium botulinum (C. bot) is a pathogenic microorganism that grows in anaerobic environments, where there is no oxygen. C. bot is responsible for a disease called botulism. It occurs after consuming food contaminated with the toxin produced by this pathogen. C. bot growth and toxin formation is a hazard that is reasonably likely to occur and must be controlled in reduced-oxygen packaged (ROP) seafood products, particularly C. bot type E and nonproteolytic types B and F, which are commonly associated with fish and fishery products/seafood. Vacuum-packaged products can be a suitable environment for the pathogen to grow.

The minimum temperature at which C. bot type E and nonproteolytic types B and F grow and produce toxin is 3.3°C (38°F) (FDA, 2011). To ensure the maintenance of temperatures below 3.3°C for fresh products, the use of a time-temperature indicator (TTI) on the smallest unit of packaging, which is typically an ROP package, may be required. TTIs provide an irreversible change of color if the refrigerated seafood packages reach an unsafe temperature over time.

Listeria monocytogenes is one of the most heat-resistant non-spore forming pathogens. It can grow in oxygen-free environments and at low refrigeration temperatures. The survival and growth potential of L. monocytogenes on ready-to-eat (RTE) seafood is a major concern. The USDA Food Safety and Inspection Service maintain a zero-tolerance policy for L. monocytogenes (L. monocytogenes must be absent from 25-gram samples) in RTE products. L. monocytogenes can be controlled by adequate personnel hygiene, cleaning and maintenance of equipment, sanitation, and/or sufficient time/temperature combinations that destroy L. monocytogenes (6 log reduction).

Overall objectives of our work

Refrigerated, vacuum-packed scallops and lobsters tails ready to be sous vide–cooked offer increased convenience to the foodservice industry and quality to consumers as interest in sous vide cooking grows. However, to make this process viable, extended refrigerated shelf life is necessary to provide enough time for distribution. HPP can extend the shelf life of these products, but it is important to assess changes in quality properties (such as texture and color) and consumer acceptability of scallops and lobster tails due to the application of HPP so we can recommend optimal processing to the foodservice industry.

Physical and chemical analyses and consumer acceptability testing

Research at the University of Maine assessed…

- Pressure: 150 and 350 MPa

- Holding time: 5 and 10 minutes

- Temperature: 5°C

- HPP-treated scallops and lobster tails were sous vide–cooked at 65°C for 10 minutes.

- Physical and chemical analyses and consumer acceptability testing were performed on HPP and subsequently, sous vide–cooked scallops and lobster tails.

- The refrigerated shelf life of HPP scallops and lobster tails meant for sous vide cooking was also assessed over 40 days.

Note: It is important to use moderate pressures for scallops and lobster tails because pressures above 400 MPa are known to damage the textural integrity of seafood.

Results

Scallops results

- The moisture content (the amount of water in the meat), weight loss, and water-holding capacity (the ability of meat to retain its own water) of HPP and subsequently sous vide–cooked scallops was not significantly different from unprocessed samples.

- HPP changed the appearance of raw scallop meat, making the meat appear whiter.

- The use of instrumentation to analyze and quantify texture attributes of raw scallops such as toughness was the same after HPP for all treatments. However, higher pressure (350 MPa) and longer time (10 minutes) of HPP treatment resulted in harder (instrumental analysis) scallops after sous vide cooking compared to the unprocessed control.

- Consumer acceptability of HPP-treated samples did not differ from the unprocessed control for aroma, appearance, texture, flavor, and overall acceptability of sous vide–cooked scallops.

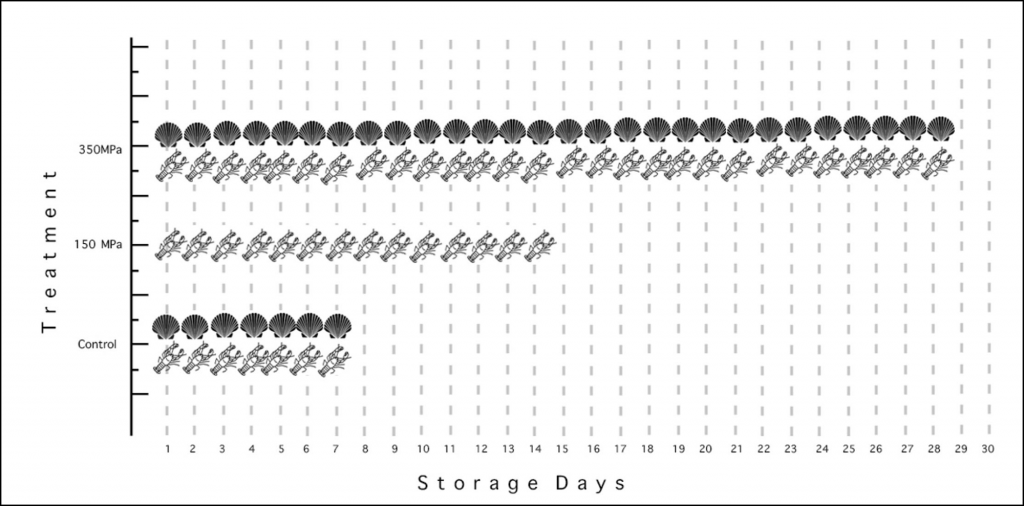

- Shelf life (Figure 4) of HPP-treated scallops at 350 MPa for 5 or 10 minutes was three times longer (~1 month) than unprocessed controls (1 week).

Lobster results

- HPP did not significantly affect moisture content, water-holding capacity, or weight loss of raw or sous vide–cooked lobster tails.

- Application of moderate pressures (150 MPa and 350 MPa) significantly influenced the color and texture of lobster tails, but processing time (5 or 10 minutes) showed less effect.

- Pressurization at 350 MPa significantly increased lightness and shear force, but these HPP-induced changes did not influence the overall consumer acceptability of the sous vide–cooked lobster tails. In addition, the higher pressure (350 MPa) samples better-met consumers’ expectations for lobster texture and color.

- Higher pressure (350 MPa) extended the refrigerated shelf life (28 days) of prepackaged raw shucked (meat removed from the shell) lobster tails by 21 days for non-HPP and by 14 days for the 150 MPa treatment.

Take-home messages

- Sous vide cooking is becoming increasingly popular and is a convenient method to produce perfectly cooked scallops and lobsters at home or in a food service environment.

- HPP can be used as a potential pre-treatment to develop refrigeration-stable, high-quality scallops and lobster tails ready for sous vide cooking with extended shelf life.

- HPP at 350 MPa extended the shelf life of raw scallops and lobster tails three-fold compared to the non-HPP control.

- Consumers rated the non-HPP and HPP sous vide–cooked scallops and lobster tails similarly, suggesting that there were no significant effects of HPP on consumer acceptability.

References

Bolton, J. (2015). Reduced Oxygen Packaging (ROP): Requirements and Guidelines in Maine for Food Service. Cooperative Extension Publications, Bulletin #3107, Reduced Oxygen Packaging (ROP): Requirements and Guidelines in Maine for Food Service.

Food and Drug Administration. (Fourth Edition, August 2019). FDA Fish and Fishery Products Hazards and Controls Guidance.

Humaid, S., Nayyar, D., Bolton, J., & Skonberg, D. I. (2019). Physicochemical Properties and Consumer Acceptance of High‐Pressure Processed, Sous Vide‐Cooked Lobster Tails. Journal of Food Science. doi: 10.1111/1750-3841.14954

Information in this publication is provided purely for educational purposes. No responsibility is assumed for any problems associated with the use of products or services mentioned. No endorsement of products or companies is intended, nor is criticism of unnamed products or companies implied.

© 2020

Call 800.287.0274 (in Maine), or 207.581.3188, for information on publications and program offerings from University of Maine Cooperative Extension, or visit extension.umaine.edu.

In complying with the letter and spirit of applicable laws and pursuing its own goals of diversity, the University of Maine System does not discriminate on the grounds of race, color, religion, sex, sexual orientation, transgender status, gender, gender identity or expression, ethnicity, national origin, citizenship status, familial status, ancestry, age, disability physical or mental, genetic information, or veterans or military status in employment, education, and all other programs and activities. The University provides reasonable accommodations to qualified individuals with disabilities upon request. The following person has been designated to handle inquiries regarding non-discrimination policies: Director of Institutional Equity and Title IX Services, 5713 Chadbourne Hall, Room 412, University of Maine, Orono, ME 04469-5713, 207.581.1226, TTY 711 (Maine Relay System).