Bulletin #7038, Maple Syrup Quality Control Manual

Originally developed by Kathryn Hopkins, Extension educator, University of Maine Cooperative Extension.

Updated and revised by Jason Lilley, Assistant Extension Professor, Sustainable Agriculture and Maple Industry Educator, University of Maine Cooperative Extension (2025).

For information about UMaine Extension programs and resources, visit extension.umaine.edu.

Find more of our publications and books at extension.umaine.edu/publications/.

Table of Contents

- Cleanliness and Maple Syrup Quality

- Quality Begins in the Sugarbush

- Tubing Systems

- Tree Tapping

- Sap Collection

- Quality Continues in the Sugarhouse: Processing Sap

- Maple Syrup Quality Control Puts Emphasis on Flavor

- Accurate Grading of Syrup to Ensure High Quality

- Syrup Filtering

- Grading Syrup for the Retail Container

- Reducing Lead in Syrup

- After Sugaring: Quality Begins for the Next Season

- Summary

- Appendix

- Additional Reading

Cleanliness and Maple Syrup Quality

The most important contributor to maple syrup quality is cleanliness. Microorganisms, bacteria, and yeast are enemies of high-quality syrup. They affect both color and flavor. Since these culprits are found on unclean equipment and may grow rapidly in sap and syrup, careful sanitary practices are critical when collecting sap and making, packing, and storing syrup.

Sanitizers and Maple Syrup Quality

Although cleanliness is a “must,” most cleaning compounds cannot be used in maple production. Household detergents, soaps that have any fragrance, and iodine-based dairy sanitizers should not be used to sanitize syrup production equipment. They can ruin the syrup flavor, making the syrup unsaleable.

Any cleaning or sanitizing products used must be handled according to the label. Some commonly used food contact surface-approved sanitizers include household bleach, peroxyacetic acid compounds, hydrogen peroxide, and quaternary ammonium compounds. Be sure to check with your organic certifier for a list of allowable materials, if applicable.

One part of unscented household chlorine bleach (such as unscented Clorox™) to 20 parts of clean water may be used for rinsing, but you’ll need to flush equipment afterward with clean, potable water. Don’t use a stronger solution or leave the solution in contact with equipment for an extended period of time because flavor problems may result.

NOTE: Household chlorine bleach is generally a 5.25 percent sodium hypochlorite solution. Commercial bleaches are stronger. The “one part bleach to 20 parts water” noted in this manual refers to household bleach.

Despite the type of sanitizer used, triple rinse with warm, potable water, or follow the rinsing instructions listed on the sanitizer label (ex. RO wash cycles). Safely neutralize and dispose of wash and rinse water according to label instructions and local regulations.

Remember that anything added to sap, even in minute quantities, will become concentrated as the sap is boiled to syrup, causing an off flavor. Plenty of “elbow grease” and lots of clean, hot water (especially permeate from the RO) are the best cleaning agents for maple syrup equipment.

Quality Begins in the Sugarbush

The equipment used to collect sap will greatly impact your final product. Every aspect, from your drill bit to the releaser and storage tanks, has the potential to influence syrup quality.

Spouts and Droplines

There are many types of spouts on the market. Options from low porosity plastics, stainless steel, and even those containing silver nanoparticles. If reusing spouts, sanitize them by cleaning off debris and dip-rinsing them in a chlorine bleach solution (one part of unscented chlorine bleach to 20 parts of water). Then rinse them thoroughly in hot water. (Metal spouts may be boiled in clean water as a substitute for the dip-rinse.) It is recommended that spouts and droplines be replaced every 3 years. Using new or sanitized spout and droplines will keep the tap hole open longer, increase sap yield, and help keep tubing lines free of microorganisms.

Buckets and Pails

Scrub buckets and pails thoroughly by hand or by machine with hot water. If you use a chlorine bleach solution to sanitize them (one part unscented household chlorine bleach to 20 parts water), take care to rinse each bucket well with warm water. Avoid scented soaps, and always rinse soaps with sufficient warm water. Do this at the end of the season so next year’s work is easier, to fully remove soap residues, and to prevent metal deterioration. Avoid non-food-grade plastic buckets and galvanized metal buckets for collection. Galvanized buckets very commonly contain lead that is likely to leach into the sap.

Tubing Systems

Installing Pipeline for High Quality Production

Pipelines, tubing, and conduits help the sugarmaker get the freshest possible sap to the sugarhouse. “Downhill, straight (generally), and tight” is a slogan to keep in mind when installing tubing. The pipeline that sags or is not pitched enough may retain sap, which can develop microorganisms as it ages, lowering syrup quality. Use a pipeline that’s wide enough to move sap quickly so you maintain the sap’s high quality.

Choosing Tubing for High-Quality Production

Install tubing that’s specific for maple syrup production. Tubing companies have designed products that move large volumes of sap long distances in favorable conditions. Non-commercial materials, such as black plastic water pipe, which draws heat from the sun, should be used carefully or not at all. Sap flowing long distances in dark pipelines exposed to the sun may reach temperatures as high as 80℉, even though air temperatures are much lower.

Warm sap in lines and water in storage tanks encourage microorganism growth. To prevent this problem, choose lighter-colored mainlines, especially in south-facing areas that gather more solar energy.

No matter what piping you use, ensure lines have no sags; sags trap the sap and permit bacteria growth. Strong and tight support wires and support posts, where needed, will ensure that maple tubing maintains a consistent downward slope and drainage.

If you use a pipe that is not designed specifically for sap collection, it must be made of food-grade materials.

Clean Tubing and Quality

Clean tubing is vital to maximize the production of high-quality syrup. Several research trials have demonstrated increased sap yields from a variety of sanitation practices, compared to none at all. These practices include replacing spouts and drop lines, the use of check valve spouts, injection of a bleach solution through the tubing system, and the injection of a isopropyl alcohol into the tubing system.

Note: Isopropyl alcohol is not approved for use in the U.S.

If using a bleach solution (one part unscented chlorine bleach to 20 parts water), only leave the solution in the lines for the minimum contact time listed on the label, no longer. Either rinse with potable water or permeate, or allow the first sap run to run on the ground. Off-flavored syrup can be caused by leaving bleach in the lines for an extended period of time or from residue left behind.

Avoid getting the solution on the outside of the tubing. This increases chew damage to the tubing as squirrels and other animals are drawn to the salts. Using calcium-based bleach (calcium hypochlorite) instead of sodium hypochlorite may reduce this issue. Rinsing in the fall is best to minimize the time for microbial regrowth.

While flushing tubing with a bleach solution is effective, the time and expense of this practice, as well as the risk of sap contamination, can reduce its utilization. Spout and dropline sanitation and allowing the first sap run to run on the ground are also acceptable practices.

Tree Tapping

Tap Only in White Wood

Drill all tap holes into healthy, clean, white wood. Generally, a depth of 1½ to 2 inches is recommended. When dark-colored wood shows in a hole, that bad tap hole will yield little or no sap and may spoil the flavor of large amounts of syrup.

Clean the Tap Holes

Use a sharp new drill bit for drilling tap holes. Insert spouts right after drilling. Tap them in gently to avoid any unnecessary damage or splitting of the tree. When removing wood chips, brush them with a twig or clean tool. Blowing into the hole to remove chips is an unsanitary practice. It will contaminate the tap hole.

Warning: Don’t use paraformaldehyde pellets. In the past, they were recommended for use in tap holes, and some out-of-date sugaring manuals still suggest their use. Research shows that they can damage trees. Similarly, denatured alcohol is not recommended as a disinfectant for tap holes.

Sap Collection

Timing is Important

Gather sap promptly, especially when temperatures are above freezing. Fresh, clean sap kept cool during collection and before boiling will produce the highest quality syrup. To make lighter-grade syrup and to avoid off flavors from fermentation or souring, collect and boil sap as quickly as possible.

Sap Gathering Pails

Avoid ‘non-food grade’ plastic buckets. Buckets used for strong-smelling or flavored items like pickles, grape juice, or even vanilla frosting will likely impart off flavors into the sap. Also, pay close attention to previous uses of a food-grade bucket. Used food-grade buckets could have been used for non-food uses, so be sure to ask about past uses if purchasing used buckets.

Avoid galvanized metal buckets, as these are highly likely to contain lead in the metal and in the solder. Sap bucket plastic liners can be purchased to create a barrier between the sap and the metal.

Be Observant

Maple sap and syrup pick up off-flavors easily. Be sure that particles from the exhaust pipes of tractors do not float into gathering pails or tanks. If sap has contact with any petroleum product, it is especially dangerous. Mildew, rodent nests, mothballs, manure, and other strong smells have the potential to be picked up in the sap and syrup.

Sap Ice

Ice formed in sap buckets can help keep sap cool in storage. However, many sugarmakers throw it away because they believe that it contains very little sugar. Whatever your approach, keep sap as cool as possible to minimize microbial growth before processing.

Sap Filtering

You’ll need to filter sap to remove bark, small wood shavings, and debris prior to concentrating sap in a reverse osmosis unit (RO) or processing in the evaporator. Change all sap filters often and keep them clean to avoid off-flavors. (Please see the manufacturer’s information regarding the care of filters). Many sugarmakers use filtering materials available from maple equipment suppliers to filter sap.

Sap Tanks

Keep Tanks Clean Throughout the Season. When practical, rinse and scrub gathering and storage tanks with hot water between runs. Avoid chlorine in sap tanks during the season to minimize the risk of sap contamination.

Storing Sap: Keep it Cool and Covered

Sap should not be left long in tanks when the weather is above freezing. The quality of the sap will begin to deteriorate, producing a lower-grade syrup. Ideally, sap should be processed the day it is collected.

Tanks should be located outside the sugarhouse, preferably on the north or northwest side, away from direct sunlight. A roof or loose covering over the storage tanks will prevent rain and foreign materials from lowering the quality of the sap. Some producers invest in dairy chilling tanks to hold concentrated sap under refrigeration.

Quality Continues in the Sugarhouse: Processing Sap

Prompt Processing: One Key to High Quality

For the highest quality syrup, evaporate sap as quickly as possible. Always try to evaporate sap completely before stopping. Generally, a shallow sap depth and a hot fire make for rapid syrup production, and high-grade syrup.

Reverse Osmosis

Reverse osmosis (RO) units are widely used to concentrate sap and increase evaporation efficiency. They allow the sugarmaker to remove large quantities of water before evaporation. As with all sugaring equipment, cleanliness is critical. Follow the manufacturer’s suggestions for the cleaning process and regularity. If you use an anti-bacterial storage solution or any sanitizing solution, be sure to rinse thoroughly before processing sap to avoid off-flavor and/or syrup contamination. Always check rinse water for pH to ensure that the soap is fully removed from the membranes before processing more sap.

Defoamer

Use as little defoamer as possible and make sure it’s fresh. Excessive use of some defoamers can cause waxy off-flavors.

If you use vegetable oil because of special market requirements (i.e., certified organic), take care to use the smallest possible amount. In recent years, some off-flavors due to vegetable oil have occurred. When these oils age, they will likely turn rancid and impart that rancid flavor into the syrup.

Evaporator Pan

Keep pans clean. Change draw-off sides often to prevent the accumulation of niter (sugar sand). Niter buildup can cause scorching and off-flavored (burnt-tasting) syrup. Create a set schedule to drain and fully clean pans. Niter build-up is faster when evaporating with reverse osmosis concentrate, requiring more frequent changes in the draw-off sides. Should any scorching occur, shut down and clean up the burned area to prevent off-flavors in the next batch of syrup. Some producers are investing in secondary pans to allow for swapping out dirty and clean plans during the boiling process.

Maple Syrup Quality Control Puts the Accent on Flavor

Maple syrup flavor must be guarded, from the collection of the sap to the store shelf. Flavor can be damaged from contaminated, unfiltered, or old sap; new and used filters; fermentation; mold; detergents; chemicals; rust; and more.

Accurate Grading of Syrup to Ensure High Quality

Syrup Density

Maine law requires maple syrup to be evaporated to a density between 66° and 68.9° F. degrees Brix at 68° F. Remember that syrup having a density reading below 66 percent Brix cannot legally be sold. Such syrup is more likely to ferment and grow mold. Syrup with a density above 68.9 ° F Brix may crystallize, causing consumer confusion and complaints. Various instruments can be used to check the density: hydrometers, hydrotherms, Murphy cups, and refractometers. For best results, know how the instrument works and how to protect its accuracy.

Low-Density Syrup

The principal causes of low-density syrup:

- Not making an adjustment of syrup temperature when checking density with a hydrometer. Hydrometers are highly temperature-dependent.

- Using an inaccurate hydrometer.

- Inaccurate adjustment of heavy-density syrup.

- Steam condenses on surfaces and runs into the last containers of syrup to be packed. The last syrup in the tank should not be canned unless it has been checked carefully for proper density.

Density Check at Draw-Off

Use a deep container with a narrow diameter (hydrometer cups are convenient) so that the hydrometer may be floated immediately after each draw-off. Lower the hydrometer gently. Ensure the hydrometer does not touch the bottom or sides of the cup. Make the reading at the point on the hydrometer stem that is level with the surface of the syrup (not the top of the meniscus). If using the hot test line on a hydrometer, be sure to take a reading immediately after filling the cup so that it does not have time to cool.

Syrup Refractometer

Syrup refractometers are instruments that may be used to test maple syrup density. They are available through maple equipment dealers. If you use a refractometer, be sure to follow the instructions. Occasionally, problems can occur due to incorrect instrument calibration, leading to light or heavy syrup. Most refractometers do not provide accurate readings when testing hot syrup. Refractometers should not be used to measure the density of hot syrup to prevent the cracking of the glass prism and to avoid inaccurate readings from rapid evaporation from the small amount of syrup. You can check a refractometer by comparing measurements to those taken with an accurate, tested hydrometer and a thermometer, or another refractometer.

Hydrotherm

Hydrotherms are special hydrometers with thermometers built in to locate the point on the hydrometer to measure standard density syrup. It is used like a hydrometer but allowed to sit for 30 to 40 seconds for the thermometer column in the hydrotherm to warm or cool to the syrup temperature. The Department of Agriculture does not recommend using hydrotherms because they are not calibrated to a standardized scale.

Light Transmittance Meter

A light transmittance meter is a newer tool that is used to check syrup color. In a light transmittance meter, a syrup sample is checked for color by passing light through the sample. The percent of light transmission is compared to light transmission rates set for different grades. When using one, you need to be sure there are no fingerprints on the syrup test bottle, and that the syrup sample has no bubbles or cloudiness. Any of these conditions may diminish the light that is transmitted through the sample and therefore lowers the grade of the sample.

Hydrotherm

Hydrotherms are special hydrometers with thermometers built in. There are no labeled gradients on the stem of the hydrotherm due to the internal thermometer being used as the baseline. If the thermometer is at or slightly above the surface of the syrup, the instrument tells you that the syrup is at the minimum of the legal density range. The tool must be allowed to sit for 30 to 40 seconds for the thermometer column for the hydrotherm to warm or cool to the syrup temperature. The Department of Agriculture does not recommend using hydrotherms because they are not calibrated to a standardized scale.

Murphy Cup

This tool is a hydrometer cup with a built-in dial. The dial shows brix◌ but is measuring the temperature of the syrup. This tells the user that the brix level on the dial is the reading that they should see on the floating hydrometer (in the cup). If the hydrometer reads at brix◌ listed on the dial, the syrup is 66.9◌ brix at the temperature the syrup is currently at. This eliminates the need for a thermometer when using a hydrometer and allows density to be checked at any temperature without using a temperature compensation card. These tools can be calibrated using ice water.

Automatic Draw-off

Automatic draw-offs are valves set to a specific temperature. Syrup reaches finished density at 7.5℉ above the boiling point of water on that day. When the correct temperature is set on the auto draw-off unit, the syrup can be automatically removed from the syrup pans regularly and without oversight by the syrup maker. Be sure to change the draw-off side often, especially when your scoop shows niter beginning to build up in the pan. Using a hydrometer or refractometer, test the first syrup drawn off at the new side to ensure accuracy of the unit.

Important Note: Do not scoop near the automatic draw-off until after it shuts off. Scooping near the draw-off will change the density reading of the drawn-off syrup. Clean the control when changing sides. Nylon scouring pads (unscented and soap-free) are helpful. Never use steel wool. It will scratch the pan and speed the build-up of niter.

Syrup Filtering

Care of Filters

Filters can impart off-flavors to syrups, making the product unfit for sale. Do not store cone filters, filter papers, or diatomaceous earth near mothballs, cedar closets, or scented materials. Clean filters thoroughly, dry them, and store them in a cloth bag in clean, dry, airy storage. Chlorine bleach should not be used to clean filters. Despite repeated washings, rinsings, and airings, filters that have been washed with bleach still impart off-flavors to syrup. Scented cleansers, fabric softeners, and “dryer sheets” should not be used either, and clothes washers should be avoided altogether. New filters and pre-filters must be thoroughly boiled in clean water (not in sap pans) and air dried (in the sun if possible). Use the “sniff” test to provide an added check for your filters. Musty old filters or new chemical-smelling filters should not be used.

Old, threadbare filters will cause cloudy syrup. Hold filters up to bright light to check for filter problems (cloudy syrup must be graded substandard). Remember to filter hot syrup (210 degrees F) immediately after removal from the pan. Do not stir syrup through the filter.

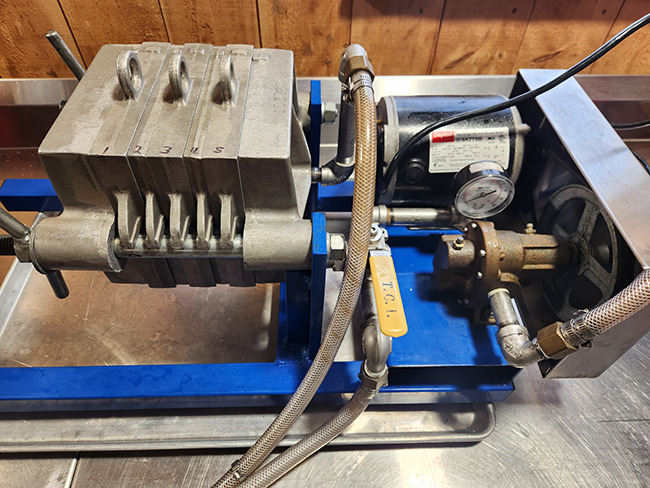

Pressure filters

Clean all pressure filter parts thoroughly with hot water prior to each reassembly.

Filter plates have numbers or patterns that indicate how the filter press should be assembled. Line up each numbered plate and smooth each cloth so that there are no creases. Put a thin rod through the plates during assembly to help maintain the correct position. The care taken with the pressure filter unit assembly will help prevent niter in finished syrup and loss of finished syrup.

Experiment to find the exact amount of filter aid (food-grade Diatomaceous Earth) needed to filter the syrup. Be sure that the diatomaceous earth used is food grade and has been stored dry. DE can absorb moisture and develop a mildew smell. If this happens, it must be discarded.

Filter papers should be changed often, and the pressure regulator should be watched to avoid building up of pressure and bursting of filter paper; careful monitoring of the filter press will help to avoid cloudy syrup.

Quality Continues in the Sugarhouse: Syrup Packing

Most sugarmakers will find it advantageous to pack some syrup in consumer-size containers during the producing season. However, at least part of the crop should be packed in bulk containers for later reheating and packing. Bulk containers offer these advantages when used for long-term storage:

- Packing syrup closer to the date of sale reduces the possibility of grade change in the consumer size container. This is especially important when packing in plastic jugs.

- The producer has greater versatility in meeting the current market demand for a specific container size and style but also maintains the potential for bulk sale.

- The potential of waste due to leftover, unwanted sizes is eliminated.

- You can blend different “runs” to achieve greater uniformity of product.

- For small producers, five-gallon cans offer similar advantages to the 30-gallon barrel.

Packing in Bulk

Here are some tips for successful bulk packing:

- Always examine bulk containers before filling them.

- Avoid bent and deformed epoxy-lined barrels. If the epoxy lining is broken, the syrup is likely to absorb a metal off-flavor.

- Use a flashlight to examine the interiors of drums for moisture, mold growth, and other contaminants.

- Use only bulk storage barrels or five-gallon cans that are rust-free, clean, and dry. Steam cleaning is the best assurance of completely clean barrels. Use a clean cloth to remove any excess moisture prior to storage.

- “Sniff” test the barrel and do not use if a foreign odor is present.

- If you are buying new barrels, purchase stainless steel barrels.

Filling Drums

For the best results, fill containers or drums with hot syrup (between 180 and 195 ℉) and fill them full. Any air space in the drum may cause problems. Use new gaskets and tighten bungs as soon as possible. Keep a sample from each drum in your freezer and identify each sample and its drum number. Then, you can repack the syrup without opening additional drums. Remember to store drums in a cool, dry place, and to educate your bulk customers in the proper storage and handling of bulk syrup.

Filling Retail Containers

These suggestions will help you ensure a high-quality product ready for retail sale.

- Keep containers of jugs closed and sealed so foreign material can’t get inside.

- Closely examine all containers for defects or debris inside and only use new containers.

- “Sniff test” empty containers. This will sometimes help you cull out unusable containers.

- Fill containers full to ensure the correct volume for the consumer and to minimize airspace that contributes to product spoilage.

Hot Packing

Always pack maple syrup hot! Packing maple syrup below 180℉ increases the chance of mold growth or spoilage. When packed at the right temperature, hot syrup sterilizes its container and prevents spoilage. When properly sealed, a vacuum prevents contamination.

The lowest safe temperature for packing syrup is 180℉ when the cap goes on. Syrup that is left uncapped for a few moments can cool sufficiently and collect enough yeast and mold spores from the air to spoil some cans in an otherwise perfect lot.

Packing syrup at temperatures higher than 180℉ (but not higher than 200℉) will result in fewer trouble-causing microorganisms. However, if temperatures are raised too high for too long, new niter may precipitate, causing cloudiness. (Refiltering reheated syrup can eliminate cloudiness.) Continue to check the temperature with a sterile thermometer immediately prior to filling the container.

For best results when heating syrup, use a continual flow method rather than heating a large volume of syrup in a vat. Some syrups may deteriorate in color and flavor when heated in large vats or pans before canning. If the syrup continually flows through several compartments while heating, it retains most of the original flavor and quality. This also makes it easier to maintain the correct packing temperature (180℉ and above).

Remember, the last container filled from any batch may not be of the correct density. When a cover is used on filter tanks, condensation may cause the last syrup to be thin. If no cover is used, the last syrup may be heavy.

When sealing plastic containers, be sure the inner seals are in container caps when they are put on.

After capping the hot syrup, immediately lay each container on its side, neck down, to sterilize the air pocket and cap. Check the closure for leaks.

When containers are cool, spot-checking a few cans for density, color, and flavor is strongly recommended. This will ensure that the syrup meets the standards for which it is labeled.

Avoid “Stack Burn”

“Stack burn” is a grade change caused by hot containers of newly canned syrup stacked together, intensifying the heat and prolonging the cooling time. Stack burn can result in the darkening of syrup by a full grade. This is a common cause of grade violations.

To prevent stack burn, make sure to cool cans quickly. Space cans and barrels apart so that air may circulate around them. Do not place cans in cartons or on pallets until cool. A fan may help to speed up the cooling process.

Code All Syrup

Code each batch of syrup as it is packed. If problems are found later, positive identification will allow you to recall only the defective syrup from the lot.

Grading Syrup for the Retail Container

Grading Kits

Grading is an important step in your production process and is required for all syrup sales. First, be sure that any temporary color grading kit is new, accurate, and right for your operation. Kits as little as 1-year old have been seen to lighten enough to create inaccurate grading. Check old kits against light transmission kits or replace them.

Color

Proper grading with visual tools can only be done against a well-lit background. A clear, blue sky is ideal; a fluorescent light is better than a regular incandescent bulb.

Stored syrup tends to darken in color, particularly when packed in plastic and ceramic jugs. Syrup that is close to the darker grade cut-off should be graded to the darker grade. This is particularly true if the syrup is stored for an extended period of time (a month or more).

Care and Storage of Canned Syrup

Temperature, air, and time are the three main enemies of all stored syrup.

Temperature:Store syrup in a clean, dry place of cool uniform temperature. Some producers use a household air conditioner in the storage room to retain syrup quality and protect the grade.

Air: Even small heads of air in containers can cause problems. Be sure to fill all containers completely.

Time: When packing or repacking into retail-size containers, plan to fill only the amount that you will sell within the next few weeks. Retail containers may lose their sales appeal (ex., Holiday packaging), and the syrup may lose flavor, color, and grade when stored for long periods. Grade loss is especially true of plastic containers, in which syrup has been found to darken as much as one grade in only three months.

Reducing Lead in Syrup

The maple syrup industry has come a long way to reduce the amount of lead in maple equipment. That said, it is the responsibility of all maple producers to ensure that pure maple syrup is absent from lead and other heavy metals. Test levels must be below allowable levels (below 250 ppb). If syrup tests higher than that level, producers must identify the source of the contamination and quickly act to eliminate it.

Lead does not come from trees. Sap collected using lead-free plastic has virtually no lead in it. Sap collecting and syrup-making materials that contain lead include 50/50 solder, which was used before 1995 for evaporators, tanks, and some buckets (Leader Evaporator switched to lead-free solder in 1991); galvanized equipment made before 1994; most brass and bronze; and terneplate, an alloy with a high lead content used for some older equipment.

Lead-containing buckets begin to leach lead into sap within the first few hours, and lead is continued to be added to sap if it is in contact with metal surfaces. Storage of sap in buckets for several days, which may occur when sap runs slowly, can result in very high sap lead concentrations.

Sugar sand concentrates any lead in the sap as it is formed, so it should also be treated as lead-containing. Roadside dust and dirt may also contain lead. In tests of several models, all older metal spouts added lead to maple sap. Very old spouts may be made of terneplate and will leach large amounts of lead into the sap. Lead-free metal spouts are now available. Not all buckets are equal when it comes to lead. Wheeling buckets added the least amount of lead in tests, while old “tin” buckets added the most. Some old buckets have shinier terneplate bottoms; beware of these.

Metal buckets available in the current market are primarily made of aluminum. Food-grade plastic buckets for sap collection are also commonly available.

Galvanized and lead-soldered tanks also add some lead to sap, although usually less than buckets, because their surface-to-volume ratio is smaller.

In an evaporator, a lead-soldered back pan adds more lead than a lead-soldered front pan due to the many solder seams. The lead content of partially made syrup often decreases in the front pan as lead precipitates and sticks to the pan in the form of sugar sand.

After the evaporator is shut down, the lead will continue to accumulate in the partially boiled syrup from the lead solder. Draining the front pan into buckets and adding the syrup again once boiling resumes reduced lead accumulation.

Cleaning the front pan with water may remove some of the sugar sand (source of lead) and re-expose lead solder (source of lead). Water cleaning had little effect on syrup lead concentration. Frequently cleaning a lead-soldered pan with acid will likely produce higher syrup lead content.

Sugar sand may contain extremely high amounts of lead, depending on the lead concentrations in the evaporator. Good filtering is essential for keeping lead out of syrup.

In tests, cone filters were as effective as filter presses in removing lead. However, A large percentage of syrup’s lead is in a dissolved form, which is not filterable.

Bronze used in the manufacture of gear pumps usually contains lead, and these pumps can add lead to sap and syrup. Unnecessary pumping, particularly of sap, should be avoided. Other pump models that contain little or no lead are available.

Old milk cans frequently contain terneplate, an alloy with high lead content, and should never be used for syrup filtering or storage.

Syrup kept in older, heavy galvanized barrels has a much higher lead content after 8 months of storage. Newer galvanized barrels do not add appreciable lead in the same amount of time.

Standards for Lead Concentration

Standards for lead concentration are based on models of the maximum syrup consumption by children. Standards vary within the maple-producing regions of the U.S. and Canada. Syrup producers and health officials share the goal of a healthy and fine-tasting product that is safe from contaminants. We are committed to the words “Pure Maple Syrup” that we put on our cans.

Reprinted with permission from T. R. Wilmot and T.D. Perkins, Keeping Lead Out of Maple Syrup: A Guide to the Use of Sap Collecting and Syrup Making Equipment (Burlington: University of Vermont, 2000).

If you are interested in testing your syrup for lead, contact:

Endyne Inc.

160 James Brown Drive

Williston, Vermont 05495

802.879.4333

PVC Considerations

If using PVC piping to transfer sap, be sure to use food safe material. Piping labeled as “dwv” (drain, waste, vent) is not made for transferring consumable materials and contains easily leachable bisphenol A (BPA) and lead. These are also highly porous and are difficult to clean.

Maple producers should look for the NSF 51 stamp, NSF 61 stamp, and NSF PW (potable water) stamp.

Chemical Safety

Many aspects of maple production are simplified or even made possible due to the use of chemicals. Chemicals are involved with tubing sanitation, general surface sanitation, RO cleaning, and evaporator scrubbing. Many of these products are very strong acids or bases. Before purchasing and using any chemical materials, the user must do the following:

- Understand what the material is made of and if it is allowable with their system of production (i.e. certified organic)

- Obtain, read, and understand the Safety Data Sheet. These documents contain a significant amount of information about the composition of the material, associated hazards, required personal protective equipment, what to do in the case of an emergency, and disposal information.

- Prepare an appropriate storage area for the materials.

- Have and use all required personal protective equipment for each product that will be used.

- Have emergency response equipment (i.e., eye wash, rinse water, neutralizers) and plans in place in case an emergency happens.

- Communicate with family, employees, and emergency first responders about what chemicals you have on hand and where they are stored and used.

Consider all materials used in the operation. Commonly used materials, such as diatomaceous earth have a big risk of damaging eyes and respiratory tracts. Goggles and a particulate respirator should be worn with every use.

Leaving these materials in syrup can lead to off flavors in some cases and extremely dangerous health risks in others. It is the responsibility of all producers to ensure that no chemical residue is ever in contact with sap or syrup.

After Sugaring: Quality Begins for the Next Season

To ensure quality for next year, clean all equipment as soon as possible at the close of the maple season.

Care of Evaporators

Some producers allow the sap to ferment in stainless steel pans. If this method is used, watch the fermenting action carefully. When the scale loosens, scrub with a nylon pad. Rinse with clear water and dry. If chemical cleansers are used, rinse thoroughly to prevent damage to the pan and off-flavors/contamination next season.

Materials that collect on the underside of the evaporator during the season are generally corrosive to metal; if corrosive deposits are permitted to remain until the next season, holes may result in the bottom of the front pan or in the flues. To avoid damage, clean the underside of the front pan and use a brush to clean the flues. You can buy special flue brushes from maple equipment suppliers.

Painting Equipment

If sap tanks or other equipment needs to be painted, use a non-toxic epoxy paint. Paint meeting these standards is available from a maple equipment dealer. Painting at the close of the season, as opposed to the beginning of a new season, allows time for odors to dissipate, reducing the possibility of off-flavored syrup.

Storing Equipment

Store all equipment where it will remain dry, lessening the potential for rust and microbial growth.

Summary

Cleanliness and attention to detail in all parts of the production process are the most important contributions to producing high-quality maple syrup and syrup products. Producers should protect their efforts and financial investments to produce the highest-quality syrup possible. A high-quality product adds to the reputation of Maine-produced maple products and the producers’ profit level.

Appendix

- Official Grade Standards

- State Regulations and Licensing

Additional Reading

- North American Maple Syrup Producers Manual 3rd Edition.

- Handbook for Maple Grading and Judging Training, University of Maine Cooperative Extension

Information in this publication is provided purely for educational purposes. No responsibility is assumed for any problems associated with the use of products or services mentioned. No endorsement of products or companies is intended, nor is criticism of unnamed products or companies implied.

© 2002, 2007, 2010, 2016, 2025

Call 800.287.0274 (in Maine), or 207.581.3188, for information on publications and program offerings from University of Maine Cooperative Extension, or visit extension.umaine.edu.

The University of Maine System (the System) is an equal opportunity institution committed to fostering a nondiscriminatory environment and complying with all applicable nondiscrimination laws. Consistent with State and Federal law, the System does not discriminate on the basis of race, color, religion, sex, sexual orientation, transgender status, gender, gender identity or expression, ethnicity, national origin, citizenship status, familial status, ancestry, age, disability (physical or mental), genetic information, pregnancy, or veteran or military status in any aspect of its education, programs and activities, and employment. The System provides reasonable accommodations to qualified individuals with disabilities upon request. If you believe you have experienced discrimination or harassment, you are encouraged to contact the System Office of Equal Opportunity and Title IX Services at 5713 Chadbourne Hall, Room 412, Orono, ME 04469-5713, by calling 207.581.1226, or via TTY at 711 (Maine Relay System). For more information about Title IX or to file a complaint, please contact the UMS Title IX Coordinator at www.maine.edu/title-ix/.