Bulletin #1019, Understanding Wheat Quality — What Bakers and Millers Need, and What Farmers Can Do

Authors:

- Ellen Mallory, University of Maine Cooperative Extension

- Tod Bramble, Cargill, Integrated Bakery Resources, formerly King Arthur Flour Company

- Matt Williams, Aurora Mills and Farm, Linneus, Maine

- Jim Amaral, Borealis Breads, Wells, Maine

For information about UMaine Extension programs and resources, visit extension.umaine.edu.

Find more of our publications and books at extension.umaine.edu/publications/.

Increasing demand for locally grown bread wheat has created a new crop opportunity for farmers. To successfully enter this new market, growers must understand the quality characteristics that millers and bakers expect for bread wheat. This factsheet outlines the quality measures that millers and bakers evaluate to determine if a certain lot of wheat grain is suitable for bread flour, and key practices farmers can use to produce wheat that meets those standards.

- What Millers and Bakers Need for Grain Quality

- What Farmers Can Do to Produce High-Quality Bread Wheat

- Wheat Quality Measures: Quick Definitions

What Millers and Bakers Need for Grain Quality

Mycotoxin Content (DON)

The first test that a lot of grain must pass to be considered for use as bread flour is the test for the mycotoxin deoxynivalenol, abbreviated DON and also called vomitoxin. DON is produced by the Fusarium fungus that causes head blight or head scab in wheat. The disease infects wheat primarily at flowering time and thrives in wet, cool conditions. When ingested, the DON mycotoxin can cause vomiting and diarrhea in humans and livestock, and at extremely high levels, livestock abortions. The United States Food and Drug Administration has established a maximum DON guideline of 1 ppm for human products. Millers may accept grain with higher DON levels (1.5 to 2ppm) if they can reduce those levels by removing much of the infected grain through cleaning. Grain testing laboratories offer HPLC and ELISA tests for determining DON levels, with the ELISA test being significantly cheaper.

Test Weight

Test weight is more of a direct concern for millers than bakers. It is a measure of the density of the grain (i.e., the weight of a specific volume) and is generally expressed as pounds per bushel. Test weight is used as an overall indicator of grain quality and provides a rough estimate of potential flour yield. The minimum acceptable test weight for wheat is generally 56 lbs per bushel. Low test weight can be caused by poor growing conditions, especially at grain filling, and sprout damage. Test weight also varies among varieties. Cleaning can raise the test weight by removing small and damaged kernels.

Enzymatic Activity

A farmer should always remember that a kernel of wheat is, in fact, a seed. Wheat kernels, if left intact under favorable conditions, germinate to become the next generation. Enzymes play a critical role in this germination process. Inside each wheat, kernel is the “germ” (the embryonic seedling), plus a large quantity of starch (the endosperm), which is stored food for the seedling. The starch, however, must be broken down into its small sugar subunits in order to be used by the developing plant. This is accomplished by amylase enzymes that are released into the endosperm at the onset of germination.

These same enzymes are important for bread production because yeast cells also need the flour’s starch to be converted to sugar to power the fermentation process. But, too much enzyme activity leads to too much sugar, which results in a sticky dough with poor mixing strength and low loaf volume.

Farmers typically let wheat grain dry in the field and then harvest it before the germ releases the enzymes. At this stage, the seed is dormant; in the terms of a miller, the wheat (and the flour milled from it) is enzymatically stable. Water and cool temperatures, however, break seed dormancy. If grain harvest is delayed and the weather is humid, the germination process can begin in the field, causing degradation of the starches or “sprout damage” in the grain. Enzyme activity in flour milled from such grain is too high for baking. Protein degradation also occurs during this process. As little as 5% heavily sprouted wheat in a mill mix of otherwise sound grain can make the resulting flour unacceptable for bread production. For wheat grain with too little enzyme activity, millers supplement with amylase by adding malted barley flour, fungal amylase, or other enzyme sources.

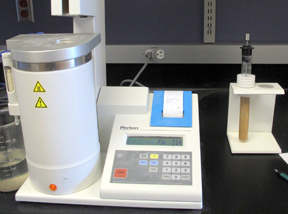

The level of enzyme activity in a given lot of grain is estimated by the falling number test. This test measures how quickly a plunger falls a certain distance in a slurry of flour and water. As enzyme activity increases, falling number values decrease. Values below 200 seconds indicate high levels of enzyme activity, while values above 350 seconds indicate low levels of enzyme activity. Generally, 250 seconds is the minimum acceptable falling number level, but this can vary from mill to mill.

Grain Protein

The gluten forming proteins of wheat, known as gliadins and glutenins, are what make bread possible. When flour and water are mixed, the gluten forming proteins begin to organize and cross-link so that a gluten web is formed. It is this protein web that allows the baker to shape the dough and have it remain in that shape instead of simply flowing across the table. This web also traps the carbon dioxide gas produced by the yeast during fermentation, allowing the loaf to rise. The concentration of gluten-forming proteins is an important number that millers and bakers evaluate in each lot of grain.

The concentration of gluten-forming proteins in the grain is measured indirectly. First, there are many other types of grain proteins, but the assumption is made that as the total amount of protein increases so does the amount of the gluten forming proteins. Second, laboratories don’t measure actual protein concentration. Rather, they measure nitrogen concentration because it is a much less expensive procedure. They then use a conversion factor to estimate protein concentration. For wheat, the conversion factor is 5.7 (i.e. “crude protein” = nitrogen x 5.7). The term “crude protein” is used to indicate that this figure could include non-protein N (like nitrate). In the U.S., crude protein values are based on 12% moisture for grain and 14% moisture for flour, whereas in Europe protein is expressed on a dry matter basis.

Typically, 12% is considered a reasonable target grain protein level for bread wheat. However, millers and artisan bakers may accept slightly lower values, especially for winter wheat, whereas higher values (13-14%) may be expected for spring wheat. While there can be differences in the quality of the protein, such that two flours with similar protein measures can give different baking results, in general, the protein concentration gives a good overall indication of the probable success of the flour in bread baking.

Dough Performance (or Baking Performance)

The final consideration is how the flour performs in the bakery when the baker combines flour and water and begins to mix. Dough performance is the culmination of all the grower has accomplished in the field as a result of sound production practices. This includes growing varieties that have demonstrated good milling and baking characteristics, using fertility practices that produce sufficiently high grain protein levels, and harvesting the wheat before sprout damage occurs.

In the U.S., a flour’s dough performance characteristics are assessed most commonly by a device known as a farinograph. The farinograph consists of a mixer that is able to measure the energy required to turn the mixer blades through the developing dough. A specified quantity of flour is mixed with water and the device begins to mix it. The farinograph can indicate the amount of water a flour sample can absorb (known as its absorption). It can also determine how quickly a dough develops and how long it can be mixed before it begins to break down (dough stability). A baker uses this information to understand how a particular flour will perform in the mixer bowl, and to calculate necessary adjustments. This can be especially useful in areas like the Northeast, where considerable variability can exist from field to field and year to year.

What Farmers Can Do to Produce High-Quality Bread Wheat

Producing wheat that meets the quality standards sought by bakers requires attention to certain aspects of wheat production and post-harvest handling. These five management strategies are key to producing high-quality bread wheat. For more detailed discussions of these topics, see the online resources list at the end of this factsheet.

1. Select a suitable variety and clean seed

Wheat varieties are grouped into market classes according to kernel hardness (hard vs. soft), color (red vs. white), and growing season (winter vs. spring). For bread flour, the hard red and hard white types are preferred because they have been selected to have higher protein levels than the soft types. Within the hard wheat class are winter types, which are planted in the fall and harvested the following summer, and spring types, which are planted in the spring and harvested in late summer. Spring types generally produce higher protein levels than winter types, yet many artisan bakers prefer winter wheat types because winter wheat protein tends to have better quality for the types of breads they typically produce — it gives a good balance of strength and extensibility and tolerates long mixing and fermentation times.

Within each wheat class are many different varieties with diverse characteristics. When selecting a variety for bread baking, pay attention to the characteristics that affect grain quality, in particular, protein levels, tolerance to Fusarium head blight, and resistance to pre-harvest sprouting. Additionally, flavor and other baking characteristics may be important to potential buyers, so it is best to consult with them about their preferences.

Sourcing high-quality seed is equally important. Low test weight and poor germination negatively affect seedling establishment and vigor, which can lead to poor grain quality. Avoid seed with high DON levels (over 1 ppm) since the disease organism that causes Fusarium head blight and produces DON can also adversely affect seedlings.

2. Choose an appropriate field and time in your rotation for wheat

To produce high-quality grain, select a site with a suitable soil type and low disease and weed pressure. Wheat performs well in well-drained, medium textured soil. For winter wheat, in particular, choose fields that do not pond or ice during the winter as this can reduce winter survival. Wheat grows best when soil pH is 6.2 − 6.8. Fields with lower soil pH should be adjusted by liming before planting.

Avoid planting wheat after wheat, corn, barley, and rye or adjacent to fields with the residue of these crops because they are all hosts of the Fusarium head blight pathogen. If you must follow one of these crops, incorporate the residue into the soil well before planting.

Choose fields with low weed pressure. Weeds impact grain quality in multiple ways: competition for nitrogen and other resources can reduce yield and protein; green weed material in harvested grain can raise moisture and cause spoilage; and weed seeds can be difficult to remove through cleaning. While winter wheat is very competitive with annual weeds, perennial weeds such as quackgrass and Canada thistle can pose serious problems. If following sod, allow sufficient time to kill perennials through tillage or herbicides before seeding wheat. For spring wheat, avoid fields with a history of weeds that germinate in early spring like wild mustard, as well as perennial weeds. In addition, to give spring wheat an advantage over emerging weeds, plant the crop as early in the spring as possible and immediately following final seedbed preparation. If warranted and conditions allow, use a spring-tine harrow or rotary hoe to control small annual weeds before crop emergence or after the 3-leaf stage.

3. Provide adequate nitrogen at the right time

The protein level of wheat is most directly affected by the amount and timing of nitrogen available to the crop during growth. In general, spring and winter wheat requires 70-80 lbs of available nitrogen per acre to produce acceptable protein levels (generally above 11.5%). This can be supplied by fertilizer, manure, plowed-down legume or sod, or a combination of these, but realize that the nitrogen in organic sources (manure, legumes, sod) is not all available during the first year. For spring wheat, a single nitrogen application before planting is usually adequate. However, for winter wheat, supplemental nitrogen applied to the growing crop in the spring (i.e. topdressing) is often needed to achieve adequate protein levels. Earlier topdress applications generally produce higher yields with little effect on protein, whereas later applications raise protein but don’t affect yields. Note that manure may not be suitable for topdressing since organic certification requires a 90-day period between application of animal manures and harvest for grains entering food-grade markets.

4. Harvest early and avoid infected areas

Timely harvest is critical to producing high-quality wheat. Once wheat reaches maturity, delaying harvest increases the risk of increased DON levels, pre-harvest sprouting, continued weed growth, and rain, which not only delays harvest further but also exacerbates the other problems. Be ready to harvest well ahead of time, and begin once the grain reaches 18-20% moisture. This requires being prepared to dry the grain down before storing (see below).

If you see evidence of Fusarium head blight in your crop, there are two things you can do to leave much of your potential vomitoxin problems in the field. First, don’t harvest heavily affected areas. Often, wet areas of a field have more severe Fusarium infections. Second, increase the combine fan speed to blow out the lighter, heavily infected “scabby” kernels or “tombstones.”

5. Be prepared to clean, dry and store the grain

Wheat grain quality must be protected after harvest through proper and prompt cleaning and drying. Grain that is too moist or contains green weedy plant material can develop increased vomitoxin levels and off-flavors and is at risk for spoilage. Dry grain to 14% moisture for storage up to 6 months, and to 13% moisture for longer storage. Be aware that both cleaning and drying result in crop “shrinkage” or yield loss, both at the farm and at the mill. However, the potential loss is necessary to improve and maintain the quality, and therefore marketability, of the crop.

Good options for cleaning grain for storage include rotary drum cleaners or “Clipper” type cleaners that use a combination of air and screens. The grain will likely need to be cleaned more thoroughly before milling, but these cleaners do an adequate job of cleaning grain for storage. For drying large amounts of grain, use batch-type or continuous flow grain dryers before storage, or use a grain bin with a perforated floor and forced heated air. For smaller amounts, a screw-in grain aerator for grain in tote bags or a wagon can work well.

Finally, grain must be stored properly to protect its quality. This means using a system that keeps the grain cool and dry and protects it from mold, rodents and insects. Avoid storing in contact with materials like concrete that transfer moisture, and avoid temperature differences between the inside and outside of the storage vessel greater than 20 degrees F, as this can cause condensation. For short-term storage (3-4 months) tote bags and wooden bunkers can be sufficient. For longer-term storage, sealed grain bins that can be aerated are the best option. Where storage insects such as the granary weevil are a concern, avoid outbreaks through proper sanitation (thoroughly clean equipment and bins between crops), aeration, and monitoring. If needed, a grain protectant such as diatomaceous earth can be used, but be sure to let your buyer know what you’ve used. If you are an organic producer, be sure the product you use is OMRI-approved.

Wheat Quality Measures: Quick Definitions

Falling Number

Definition: A measure of the level of enzymatic activity of the harvested wheat. The falling number test measures how quickly a plunger falls a certain distance in a slurry of flour and water. As enzyme activity increases, falling number values decrease. Low falling numbers can indicate that pre-harvest sprout damage has occurred.

Acceptable level: ≥250 seconds.

Importance to bakers: Bakers need some enzyme activity in the developing dough to convert starches to sugars for the yeast. Millers often add malted barley flour or other enzyme sources to achieve certain levels of activity. However, too much enzyme activity in a flour generates too much fermentable sugar, which results in reduced mixing strength, sticky dough, and low loaf volume.

Related production practices: Variety choice. Harvest timing, which is influenced by the farmer’s ability to dry grain that is harvested early.

Grain Protein

Definition: Concentration of proteins in the grain, which includes the gluten-forming proteins.

Acceptable level: 12%, although lower values may be acceptable to artisan bakers and higher values may be expected for spring wheat.

Importance to bakers: Flours with higher protein concentrations tend to have higher water absorption, stronger and more extensible dough properties, and higher loaf volume.

Related production practices: Wheat type (spring wheats tend to have higher protein levels). Variety choice. Nitrogen fertility, both total amount and the timing.

DON level

Definition: Deoxynivalenol (DON) is a toxin produced by the fungus that causes Fusarium head blight in wheat. It is also called vomitoxin.

Acceptable level: < 1ppm in the finished product for human consumption (US FDA guidance)

Importance to bakers: Bread from flour with DON levels ≥ 1ppm is considered unsafe to eat.

Related production practices: Rotation. Residue management. Variety choice. Grain cleaning.

Test Weight

Definition: The weight of a specific volume of grain, or density.

Acceptable level: ≥ 56 pounds per bushel

Importance to millers: Test weight provides an indicator of grain quality and a rough estimate of flour yield.

Related production practices: Variety choice. Timely planting and harvest.

Wheat Grain Quality Testing Services:

- University of Vermont Cereal Grains and Dry Beans

James M Jeffords Building, 63 Carrigan Dr., Burlington, VT 05405; 802.524.6501; www.uvm.edu/extension/cropsoil/grains - Great Plains Analytical Laboratory (formerly CII Laboratory Services)

9503 N. Congress Avenue, Kansas City, MO 64153; 816.891.7337 - Cumberland Valley Analytical Services, Inc.

14515 Industry Dr., Hagerstown, MD 21742; (800) 282-7588; www.foragelab.com

Online Resources:

- Northern New England Local Bread Wheat Project website

Includes reports on bread wheat variety trials and topdressing studies, as well as videos of local bread wheat systems in Quebec and Denmark. - University of North Dakota Fact Sheet: Fusarium Head Blight (Scab) of Small Grains (PDF)

https://www.ag.ndsu.edu/ndipm/publications/wheat/documents/pp804.pdf - University of Minnesota Extension Fact Sheets

Includes a series on drying and storing wheat and barley- Storing wheat and barley (https://extension.umn.edu/small-grains-harvest-and-storage/storing-wheat-and-barley)

- Drying wheat and barley (https://extension.umn.edu/small-grains-harvest-and-storage/drying-wheat-and-barley)

Reference:

- U.S. Food and Drug Administration. 2010. Guidance for Industry and FDA: Advisory Levels for Deoxynivalenol (DON) in Finished Wheat Products for Human Consumption and Grains and Grain By-Products used for Animal Feed. Division of Plant and Dairy Food Safety, Center for Food Safety and Applied Nutrition, U.S. Food and Drug Administration. 4 pp. College Park, Maryland.

Reviewed by Dr. Stephen Jones, wheat breeder and Professor at Washington State University; and Jennifer Lapidus, General Manager/Grain and Seed Coordinator at Carolina Ground, L3C and former professional baker.

Photos by Ellen Mallory unless otherwise noted.

Information in this publication is provided purely for educational purposes. No responsibility is assumed for any problems associated with the use of products or services mentioned. No endorsement of products or companies is intended, nor is criticism of unnamed products or companies implied.

© 2012, 2020

Call 800.287.0274 (in Maine), or 207.581.3188, for information on publications and program offerings from University of Maine Cooperative Extension, or visit extension.umaine.edu.

The University of Maine System (the System) is an equal opportunity institution committed to fostering a nondiscriminatory environment and complying with all applicable nondiscrimination laws. Consistent with State and Federal law, the System does not discriminate on the basis of race, color, religion, sex, sexual orientation, transgender status, gender, gender identity or expression, ethnicity, national origin, citizenship status, familial status, ancestry, age, disability (physical or mental), genetic information, pregnancy, or veteran or military status in any aspect of its education, programs and activities, and employment. The System provides reasonable accommodations to qualified individuals with disabilities upon request. If you believe you have experienced discrimination or harassment, you are encouraged to contact the System Office of Equal Opportunity and Title IX Services at 5713 Chadbourne Hall, Room 412, Orono, ME 04469-5713, by calling 207.581.1226, or via TTY at 711 (Maine Relay System). For more information about Title IX or to file a complaint, please contact the UMS Title IX Coordinator at www.maine.edu/title-ix/.