Bulletin #4079, Let’s Preserve: Steps to Success in Home Canning

Bulletin #4079, Let’s Preserve: Steps to Success in Home Canning (PDF)

The “Let’s Preserve” series was originally developed by Penn State’s College of Agricultural Sciences. Adapted with permission.

For information about UMaine Extension programs and resources, visit extension.umaine.edu.

Find more of our publications and books at extension.umaine.edu/publications/.

Table of Contents

- Start With the Best to End With the Best

- Keep Your Canned Foods Fresh

- Hot-Pack to Retain Quality

- Hot-Pack Versus Raw Pack

- Headspace Gives Food Room to Breathe

- Use the Right Jars and Lids

- Show Off Canned Food with Sparkling Jars

- Sterilizing Jars

- Top It Off with the Right Lid

- Kinds of Canners

- Boiling-Water Canners

- Boiling-Water Canning Step-by-Step

- Pressure Canners

- Pressure Canning Step-by-Step

- Allow Time for a Slow Cool-Down

- Testing Jar Seals

- Reprocessing Unsealed Jars

- Storing Canned Foods

Start With the Best to End With the Best

Your home-canned goods will be only as good as the fresh foods you start with. For high-quality, safe, home-canned foods, select the freshest foods possible. Discard diseased and moldy foods. Don’t can foods that you wouldn’t serve at your table fresh.

Fruits and vegetables are at peak quality for six to 12 hours after being picked. For this reason, produce picked from your garden or purchased from “you-pick” stands or nearby farmers’ markets is usually good for canning.

Allow peaches and pears to ripen one or more days between harvest and canning for best results. If you must delay the canning of other fresh produce, keep it refrigerated until you are ready to can.

Chill and can fresh, home-slaughtered red meats and poultry without delay. Do not can meat from diseased animals. Immediately after catching fish, remove guts, put on ice, and can within two days.

Keep Your Canned Foods Fresh

To make sure your canned foods keep the best possible color and flavor during processing and storage:

- Use only high-quality foods that are ripe and free from diseases and bruises.

- Use the hot-pack method, especially for acid foods to be processed in a boiling-water canner.

- Prevent darkening of fruits by holding them in an ascorbic acid (vitamin C) solution.

- Fill jars while food is still hot, and use the correct headspace specified in recipes.

- Tighten screw bands securely, but not as tightly as possible.

- Process and cool jars.

- Store the jars in a cool, dark place (50 to 70° F).

- Can no more food than you will use within a year.

Hot-Pack to Retain Quality

Home-canned food retains quality longer when air is removed from the food before jars are sealed. Hot-packing is the best way to remove air. It also “shrinks food so that more will fit into each jar, helps keep the food from floating, increases vacuum in sealed jars and improves shelf life.”

Hot-Pack Versus Raw Pack

Bring freshly prepared food to a boil and simmer two to five minutes. Loosely fill jars with the boiled food.

Hot-packing is the best way to can foods in a boiling-water canner. At first, the color of hot-packed foods may appear no better than that of raw-packed foods, but with time, both the color and flavor of hot-packed foods will be superior.

In raw-packing, jars are filled tightly with freshly prepared, unheated food. Some foods, especially fruit, will float in the jars. The trapped air may cause the fruit to discolor in as little as two to three months. Raw-packing is more suitable for vegetables processed in a pressure canner.

Whether food has been hot-packed or raw-packed, you should heat the juice, syrup or water added to the foods to boiling before adding it to the jars.

Headspace Gives Food Room to Breathe

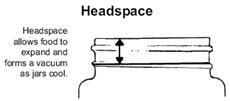

The unfilled space in a jar between the food and the lid is called headspace (see Figure 1). Leave one-fourth inch for jams and jellies, 1/2 inch for fruits and tomatoes processed in a boiling-water canner, and from one inch to 1-1/4 inches for low-acid foods to be processed in a pressure canner. Headspace allows food to expand during processing and forms a vacuum as jars cool.

Use the Right Jars and Lids

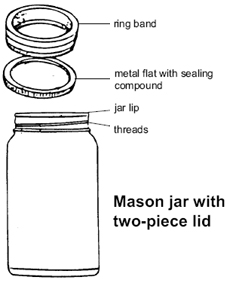

Regular and wide-mouth, Mason-type, threaded jars with self-sealing lids are the best choice for home canning (see Figure 2). They are available in 1/2 pint, quart, and 1/2 gallon sizes. The regular jar mouth opening is about 2-3/8 inches. Wide-mouth jars have openings of about three inches, which makes them easier to fill and empty. Use half-gallon jars only for canning very acid juices. Jelly jars are available in eight-ounce and 12-ounce sizes.

With careful handling, Mason jars and screw bands may be reused many times. You will need to use new lids (flats) each time, however. After jars have cooled, remove screw bands. Wash and dry bands and store in a dry area. If left on stored jars, they become hard to remove and often rust, which makes them unusable.

When you use jars and lids properly, the results are excellent seals and vacuums and little or no jar breakage.

You can use most commercial pint and quart size mayonnaise or salad dressing jars with new two-piece lids for canning acid food in boiling-water canners. However, you should expect more seal failures and jar breakage. Don’t use commercial jars in pressure canners; excessive breakage is a problem. Commercial jars with mouths that cannot be sealed with two-piece canning lids are not recommended for use in canning any food at home.

Show Off Canned Food with Sparkling Jars

Before every use, wash empty jars in hot water and detergent, and rinse well by hand. Or, wash in a dishwasher. Unrinsed detergent may cause unnatural flavors and colors in home-canned food. Remove scale or hard-water film on jars by soaking jars several hours in a solution containing one cup of vinegar (five percent acidity) per gallon of water. These washing methods do not sterilize jars.

Sterilizing Jars

Sterilize jars to be used for jams, jellies and pickled products processed less than 10 minutes. Place empty jars right side up on the rack in a boiling-water canner. Fill the canner and jars with hot (not boiling) water to one inch above the tops of the jars. Boil 10 minutes. Remove hot, sterilized jars one at a time and drain. Save the hot water for processing filled jars. Fill jars with food, adjust lids, and process as directed.

Jars used for vegetables, meats and fruits to be processed in a pressure canner do not need to be sterilized. It is also unnecessary to sterilize jars for fruits, tomatoes and pickled or fermented foods that will be processed 10 minutes or longer in a boiling-water canner.

Top It Off with the Right Lid

The two-piece, self-sealing lid is recommended for home canning. It consists of a flat, metal lid held in place during processing by a metal screw band. The flat lid is crimped around the bottom edge to form a trough, which is filled with a colored gasket compound. When jars are processed, the lid gasket softens and covers the jar sealing surface, yet allows air to escape from the jar. The gasket then forms an airtight seal as the jar cools. Gaskets in unused lids work well for at least five years from their date of manufacture if stored in a cool, dry area. Older, unused lids or improperly stored lids may fail to seal.

Buy only the quantity of lids you will use in a year. To ensure a good seal, carefully follow the manufacturer’s directions. Examine all metal lids carefully. Do not use old, dented or deformed lids, or lids with gaps or other defects in the sealing gasket.

After filling jars with food, release air bubbles by inserting a flat, plastic spatula between the food and the jar. (Don’t use a metal spatula or knife.) Slowly turn the jar, and move the spatula up and down to allow air bubbles to escape. Adjust the headspace, and clean the jar rim (sealing surface) with a clean, damp paper towel. Uncleaned jar-sealing surfaces may cause seal failures.

Place the lid, gasket down, onto the cleaned jar rim. Then fit the metal screw band over the flat lid. Follow the lid manufacturer’s guidelines for tightening the jar lids properly.

Do not retighten lids after processing jars. As jars cool, the contents in the jar contract, pulling the self-sealing lid firmly against the jar to form a high vacuum. If screw bands are too loose, liquid may escape from jars during processing, and seals may fail. If screw bands are too tight, air cannot vent during the processing, and food will discolor during storage. Over-tightening may also cause lids to buckle and jars to break, especially with raw-packed, pressure-processed food.

Kinds of Canners

There are two main types of canners for home-canning: boiling-water canners and pressure canners. Most hold seven quart-sized jars or eight to nine pint-sized jars. Small pressure canners hold four quart-sized jars: some large pressure canners hold 18 pint-sized jars in two layers, but only seven quart-sized jars. Never use pressure saucepans with smaller volume capacities for canning.

You must process low-acid foods, like vegetables, meat, poultry and fish, in a pressure canner to prevent botulism, an often fatal type of foodborne illness. Although pressure canners may also be used for processing some acid foods, such as fruits, boiling-water canners are recommended for this purpose because they are faster. Please refer to UMaine Extension’s fact sheet Food Canning Basics, Bulletin #4078, for more information on safe home canning.

Boiling-Water Canners

Boiling-water canners are made of aluminum or porcelain-covered steel. They have removable, perforated racks and fitted lids. The canner must be deep enough so that at least one inch of briskly boiling water will cover the tops of jars during processing. Boiling-water canners with ridged bottoms can be used only on a gas range. Boiling-water canners with flat bottoms can be used on either a gas or electric range. To ensure uniform processing of all jars with an electric range, the canner should be no more than four inches wider than the burner (when centered over the burner, the canner will overhang the burner by two inches all the way around).

Boiling-Water Canning Step-by-Step

- Fill the canner halfway with water.

- Preheat water to 140° F for raw-packed foods and to 180° F for hot-packed foods.

- Load filled jars, fitted with lids, into the canner rack and use the handles to lower the rack into the water; or fill the canner, one jar at a time, with a jar lifter.

- Add more boiling water, if needed, so the water level is at least one inch above the jar tops. Do not pour directly on jar tops.

- Turn heat to its highest position until water boils vigorously.

- Set a timer for the minutes required for processing the food.

- Cover the canner, and lower the heat setting to maintain a gentle boil for the time required.

- Add more boiling water, if needed, to keep the water level at least one inch above the jars.

- When jars have been processed for the recommended time, turn off the heat and remove the canner lid.

- Use a jar lifter to remove the jars, and place them on a towel. Leave at least one inch of space between the jars during cooling.

Pressure Canners

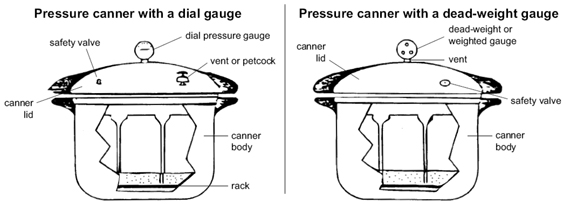

Pressure canners for use in the home have been extensively redesigned in recent years. Models made before the 1970s were heavy walled kettles with clamp-on or turn-on lids. They were fitted with a dial gauge, a vent port in the form of a petcock or counterweight, and a safety fuse.

Modern pressure canners are lightweight, thin-walled kettles; most have turn-on lids. They have a jar rack, gasket, dial or weighted gauge, and automatic vent/cover lock, a vent port (steam vent) to be closed with counterweight or weighted gauge and a safety valve (see Figure 3).

To be absolutely certain you are getting a true reading of the temperature inside your pressure canner you must:

-

Operate the canner at the pressure and time specified in UMaine Extension’s guide sheets. See Food Canning Basics, Bulletin #4078.

-

Get rid of air trapped inside the pressure canner by venting. Air trapped inside the canner lowers the temperature and results in under-processing. Despite manufacturer’s directions, to be safe you should vent all types of pressure canners 10 minutes before pressurizing.

To vent a canner, leave the vent port uncovered on newer models, or manually open petcocks (on some older models).Then, heat the filled canner with its lid locked into place until the water boils and generates steam that escapes through the petcock or vent port. When steam first escapes, set a timer for 10 minutes. After venting 10 minutes, close the petcock, or place the counterweight or weighted gauge over the vent port to pressurize the canner.

Weighted-gauge models exhaust tiny amounts of air and steam each time their gauge rocks or jiggles during processing. They control pressure precisely and do not need watching during processing. The sound of the weight rocking or jiggling indicates that the canner is maintaining the recommended pressure. Weighted gauges do not have to be checked for accuracy.

-

Check dial gauges for accuracy before use each year, and replace them if they read high by more than one pound at five pounds, 10 pounds or 15 pounds of pressure. Low readings cause over-processing and also indicate that the gauge should be replaced. Gauges may be checked at most UMaine Extension county offices.

-

Handle canner lid gaskets carefully, and clean them according to the manufacturer’s directions. Nicked or dried gaskets will allow steam leaks during pressurization of canners. Keep gaskets clean between uses. Gaskets on older-model canners may require a light coat of vegetable oil once each year. Gaskets on newer-model canners are prelubricated and do not need oiling. To find out if your canner gasket has been prelubricated, check the manual.

Lid safety valves are thin metal inserts or rubber plugs that relieve excess pressure in the canner. Do not pick at or scratch valves while cleaning lids.

-

Use only canners that have the Underwriter’s Laboratory (UL) approval for safety.

-

When ordering parts, be sure to give your canner model number and describe the parts needed. Replacement gauges and other parts for canners are often available at stores that sell canning equipment or from canner manufacturers.

Pressure Canning Step-by-Step

-

Put two to three inches of hot water in the canner. Place filled jars on the rack using a jar lifter. Fasten canner lid securely.

-

Leave weight off vent port or open petcock. Heat at the highest setting until steam flows freely from the petcock or vent port.

-

Maintain high heat setting, let steam vent 10 minutes, and then place weight on vent port or close petcock. The canner will pressurize during the next three to five minutes.

-

Start timing the process when the pressure reading on the dial indicates that the recommended pressure has been reached, or when the weighted gauge begins to jiggle or rock.

-

Regulate heat under the canner to maintain a steady pressure at or slightly above the correct gauge pressure. Quick and large pressure changes during processing may cause jars to lose liquid. Weighted gauges on Mirro canners should jiggle about two or three times per minute. On Presto canners, they should rock slowly throughout the process.

-

When the timing process is completed, remove the canner from heat, and let the canner depressurize. Do not force-cool the canner. Forced cooling may result in food spoilage.Cooling the canner with cold running water or opening the vent port before the canner is fully depressurized will cause liquid to escape from jars and seal failures. Force-cooling may also warp the canner lid on older-model canners and cause steam leaks.

Time the depressurization of older models. Standard-size, heavy-walled canners require about 30 minutes when loaded with pints and 45 minutes with quarts. Newer, thin-walled canners cool more rapidly. They are equipped with vent locks that drop to a normal position, allowing the canner to be opened when the canner is depressurized.

-

After the canner is depressurized, remove the weight from the vent port or open the petcock. Wait two minutes, unfasten the lid, and remove it carefully, tilting it away from you so the steam does not burn your face.

-

Use a jar lifter to remove the jars, and place them on a towel. Leave at least one inch of space between the jars during cooling.

Allow Time for a Slow Cool-Down

When removing hot jars from a canner, do not retighten their lids. Retightening of hot lids may cut through the gasket and cause seal failures. Cool the jars at room temperature for 12 to 24 hours on towels or racks. The food level and liquid volume of raw-packed jars will be noticeably lower after cooling. Air is exhausted during processing, and food shrinks. If a jar loses excessive liquid during processing, do not open it to add more liquid.

Testing Jar Seals

After cooling jars, remove the screw bands and test seals using one of these methods:

- Press the middle of the lid. If it springs up when released, the lid is not sealed.

- Tap the lid with the bottom of a teaspoon. If the jar is sealed correctly, it will make a ringing, high-pitched sound. A dull sound means the lid is not sealed. (Food touching the underside of the lid, however, will also cause a dull sound. You may need to test seal by another method.)

- Hold the jar at eye level, and look across the lid. The lid should be concave (curved down slightly in the center). If the center of the lid is either flat or bulging, it may not be sealed.

Reprocessing Unsealed Jars

If a lid fails to seal, you must reprocess within 24 hours. Remove the lid and check the jar-sealing surface for tiny nicks. If necessary, change the jar. Always use a new, properly prepared lid, and reprocess using the same processing time. The quality of reprocessed food is poor.

Instead of reprocessing, unsealed jars of food can be frozen if headspace is adjusted to 1-1/2 inches and food is in a freezer-safe container. Single, unsealed jars can be refrigerated and used within several days.

Storing Canned Foods

Tightly sealed, cooled jars are ready to be stored. Remove screw bands, wash the lids and jars to remove food residue, rinse and dry jars. Label and date jars, and store them in a clean, cool, dark, dry place—50 to 70° F is ideal. Do not store jars above 95° F, or near hot pipes, a range, a furnace, in an uninsulated attic or in direct sunlight. Under conditions such as these, food will lose quality in a few weeks or months and may spoil. Dampness may corrode metal lids, break seals, and allow recontamination and spoilage.

Freezing of canned foods will not cause spoilage unless jars become unsealed and recontaminated. Freezing and thawing will soften food, however. If you must store jars where they may freeze, wrap them in newspapers, place them in heavy cartons, and cover with more newspapers and blankets.

Information in this publication is provided purely for educational purposes. No responsibility is assumed for any problems associated with the use of products or services mentioned. No endorsement of products or companies is intended, nor is criticism of unnamed products or companies implied.

© 1991, 2007

Call 800.287.0274 (in Maine), or 207.581.3188, for information on publications and program offerings from University of Maine Cooperative Extension, or visit extension.umaine.edu.

The University of Maine System (the System) is an equal opportunity institution committed to fostering a nondiscriminatory environment and complying with all applicable nondiscrimination laws. Consistent with State and Federal law, the System does not discriminate on the basis of race, color, religion, sex, sexual orientation, transgender status, gender, gender identity or expression, ethnicity, national origin, citizenship status, familial status, ancestry, age, disability (physical or mental), genetic information, pregnancy, or veteran or military status in any aspect of its education, programs and activities, and employment. The System provides reasonable accommodations to qualified individuals with disabilities upon request. If you believe you have experienced discrimination or harassment, you are encouraged to contact the System Office of Equal Opportunity and Title IX Services at 5713 Chadbourne Hall, Room 412, Orono, ME 04469-5713, by calling 207.581.1226, or via TTY at 711 (Maine Relay System). For more information about Title IX or to file a complaint, please contact the UMS Title IX Coordinator at www.maine.edu/title-ix/.