Bulletin #1075, Tarping in the Northeast: General Logistics of Tarp Management

Tarp Size and Thickness

The typical size tarp for occultation and solarization ranges between 16-50’ wide and 50-100’ long. Weight and bulk is often the limiting factor to size selection. For example, a 50’ x 100’ 5 mil silage tarp weighs 150 lb when clean and dry. In addition to handling considerations, bed width and layout typically determine the desired dimensions of tarps. Areas with raised beds require larger tarp sizes to account for the depression of the walkways. Silage tarps are available in a wide range of sizes, making them easily customizable. They can be cut to the desired length or width based on bed size and number of beds. Landscape fabric is typically available in long, narrow rolls (up to 16’ wide).

It is possible to purchase tarps less than 4 mil thick, but they often do not last longer than a single season. While 5-6 mil tarps contain more plastic, they typically last multiple seasons (see Table 1 for best estimates). Landscape fabric is sold by weight or tensile strength, rather than thickness.

Price Comparisons

The following chart compares the cost to cover a 32’ x 100’ area with the various tarp types. Sourcing tarps through local suppliers (e.g. farm supply and equipment dealers) can avoid substantial shipping costs.

| Tarp Type | Material | Years Use | Thickness | Range of Prices to Cover 32’x100′ (New) | Estimated price per Year | Permeability | NOTES |

|---|---|---|---|---|---|---|---|

| Silage or Ag Plastic | Polyethylene | 3-5 | 5-6 mil | $130-$202 | $26-$67 | Impermeable | One side black, one side white or black on black. |

| Landscape / Woven Fabric | Polypropylene | 5-7 | 2.2 – 4 oz | $184-$224 | $26-$45 | Semi-permeable | Usually available in narrow rolls (7-16′ wide) |

| Clear Plastic | Polyethylene | 3-5 | 6 mil | $253-$535 | $51-$178 | Impermeable | Can use old greenhouse plastic; edges must be buried to avoid moisture and heat loss. |

| Billboard | Polyvinyl Chloride (PVC) | 6-10 | 11 mil | $448-$540 | $45-$90 | Impermeable | Typically only available in smaller dimensions; not allowable under NOP Rules. |

| Blue Tarp | Polyethylene | 2-4 | 4-5 mil | $90-$112 | $23-$56 | Semi-permeable | Not as effective for field tarping purposes. |

| *Longevity is based on best estimates from experienced farmers using good storage conditions **Prices do not include shipping costs | |||||||

Securing Tarps

Tarps that blow in the wind can be dangerous to people, infrastructure, and livestock in the area—not to mention ineffective and unsightly. The majority of farmers using tarps secure them with sandbags. Once filled, sandbags are easy to move and store. Sandbags (10-15lbs) should be set close to the edges of the tarps, approximately every 5’ down the edges and less frequently across the middle of the tarp (10’). Placing them down each bed walkway works well to prevent air from entering under the tarp and lifting it. More sandbags are recommended on exposed, windy sites and when tarping for long durations or over winter. It is better to put on extra sandbags than to return to windblown tarps that need to be readjusted. Lighter tarps need to be secured more tightly than heavier ones.

Other options include 1 ft3 cinder blocks. The edges of cinder blocks grab the tarp well, but more care needs to be taken to prevent damaging the tarp. Blocks can be easily stacked on pallets for storage; with a pallet fork on a tractor, this process is much easier. For woven landscape fabric, steel garden staples work well and tools exist that make it possible to insert them quickly while standing. Burying the edges of tarps with soil works especially well for clear tarps, for which it is important to seal edges more tightly to create the hot conditions needed to solarize. The case studies illustrate some farmers’ preferences for different edge securement methods and their reasons.

Labor Requirements

The hand labor requirements to apply and remove tarps vary by tarp size, securement method, and field conditions. It takes two people approximately 20 minutes to apply a 24’ x 100’ tarp if sandbags are ready to go and close by. It takes a similar amount of time, about 25 minutes, to remove a tarp and sandbags from a field. This includes the time needed to fold them when putting them away for storage. Wind can severely hamper tarping operations, as can ponding on tarps. Having more than two people may be necessary and desired under some conditions. Tarps may need adjustment, especially after days with high winds. In addition to applying and removing tarps, moving them among fields can be time-consuming and challenging. One way to reduce this labor is by planning the rotation to keep tarped beds in close proximity. Some farmers have a dedicated set of beds for tarping. If the planning and timing in the rotation are right, tarps can be peeled back one or several beds at a time for succession plantings or removed by sliding them over adjacent beds. Once tarping systems are more established, another labor-saving strategy is to acquire more tarps and dedicate them to specific fields or areas on the farm.

In research from New York, a no-till tarp system required equal or more labor for production compared to conventional tillage, but this labor was significantly shifted. Equipment and hand weeding labor can be reduced with significant labor added for tarp application and removal. However, all labor is not equal and adding tarping labor in early spring or late fall when wet field conditions limit field access, or when other farm demands are not at their peak, can have clear advantages.

All labor is not equal and adding tarping labor in early spring or late fall when wet field conditions limit field access, or when other farm demands are not at their peak, can have clear advantages.

Longevity and Storage

Breakdown of tarps is typically a result of both in-field damage and storage conditions. Silage tarps, greenhouse plastic, and landscape fabric are all UV stabilized, lasting many years even in direct sunlight. However, damage occurs in the field from deer and other animal traffic, crop stubble, and blocks or garden staples creating large tears. Landscape fabric is less likely to be damaged by these factors. In storage, rodent damage can be significant. Preventing these sources of damage can maximize tarp longevity and efficacy. Minimizing soil and plant debris sticking to the tarps when folding them and storing them outdoors can help to deter rodents. If outdoors, it is recommended to store them off the ground (e.g. on a pallet). The average lifespan of tarps varies by type from 2-10 years, with some common choices for more durable tarps listed in Table 1.

Drawbacks and Considerations

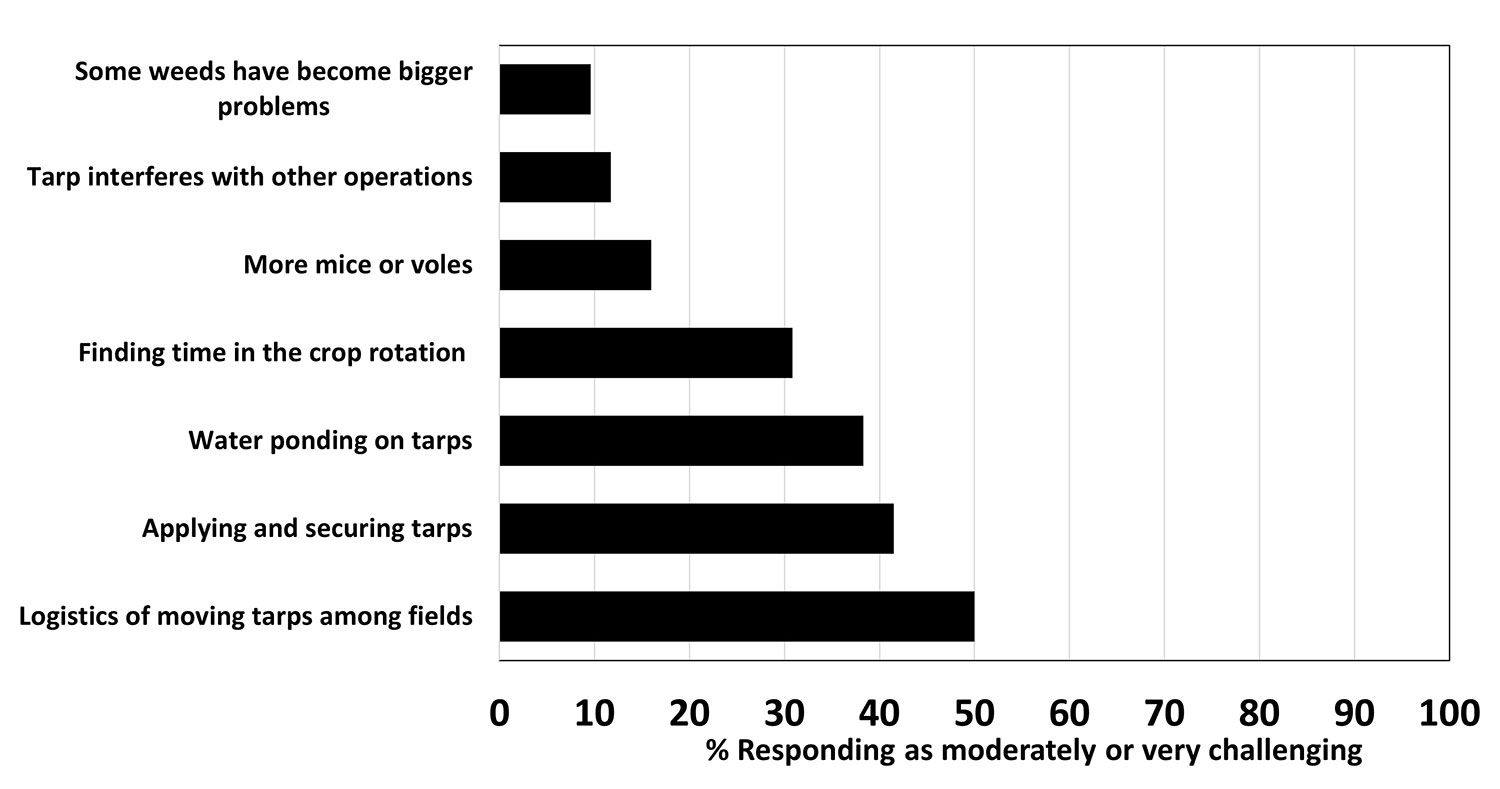

Farmers who use tarps cite the logistics of moving them among fields as the biggest management challenge (Rangarajan 2019). Ponding on impermeable tarps is also challenging under wet conditions, and runoff from tarps can end up in a neighboring bed or another part of the field. Water can make tarp removal difficult and messy. If possible, directing water to sod alleys when removing tarps can help mitigate some of this problem. The use of tarps can lead to increased habitat for rodents and—partially as a consequence—snakes. Caution should be taken if a crop that is susceptible to rodent damage is grown near a tarped field, as this may have food safety implications. It is also possible that moving tarps between fields could introduce soil-borne diseases into previously uninfected fields. If soil-borne disease is a major concern, tarps dedicated to specific fields may be advisable unless tarps can be cleaned and sanitized. Operating equipment along the edges of tarps can be difficult, and sandbags can get in the way when managing neighboring untarped beds.

In complying with the letter and spirit of applicable laws and pursuing its own goals of diversity, the University of Maine System does not discriminate on the grounds of race, color, religion, sex, sexual orientation, transgender status, gender, gender identity or expression, ethnicity, national origin, citizenship status, familial status, ancestry, age, disability physical or mental, genetic information, or veterans or military status in employment, education, and all other programs and activities. The University provides reasonable accommodations to qualified individuals with disabilities upon request. The following person has been designated to handle inquiries regarding non-discrimination policies: Director of Institutional Equity and Title IX Services, 5713 Chadbourne Hall, Room 412, University of Maine, Orono, ME 04469-5713, 207.581.1226, TTY 711 (Maine Relay System).