Sources of Rakes and Harvesters

Prepared by David E. Yarborough, Extension Blueberry Specialist, The University of Maine Cooperative Extension, Orono, ME 04469. Revised February 2011.

Hand Rakes

The Hubbard Rake Company

1561 Mason Bay Road

Jonesport, Maine 04649

Tel: 207.497.5949

Email: hrakes@gwi.net

Website: www.hubbardrakes.com

Machine Harvesters, Pickers, and Winnowers

Maine Blueberry Equipment Company

257 Tibbettstown Road

Columbia Falls, Maine 04623

Tel: 207.483.4156

The Emerson harvester is produced by Zane Emerson. It has a rotating head with a conveyor to bring it into a plastic box (holds 10 kg) behind it.

J.M. Bouchard et Fils Inc.

741 Principale

St-Augustin, Quebec, Canada G0W 1K0

Tel : 418.374.2342.

The Bouchard Rake ( 80 cm head width) has a flat rake head that must be raised to empty into a box behind it (holds 10kg). It is slower to operate than the Emerson harvester.

Doug Bragg Enterprises

96 Bragg Road

Collingwood, Nova Scotia Canada B0M 1E0

Tel: 902.686.3254

Website: www.dbe.ca

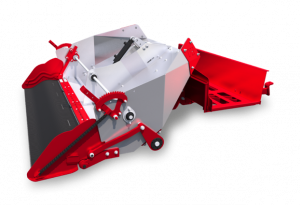

Doug Bragg Enterprises Ltd. Mechanical Blueberry Harvester consists of a reel-type picking head. The head is side mounted to a tractor in such a manner as to allow the picking head to follow contours of the ground. The reel rotates within the head in the same direction as the tractor wheels. This rotation is at a speed in ratio to the forward motion of the tractor. As the comb type-picking bars rake the blueberries from the plants they are carried around the reel and deposited in a conveyor. This conveyor delivers them to another longer conveyor, which carries them to the rear three-point-hitch mounted loading platform. As the berries fall from the conveyor a blower cleans them. All units are equipped with an electric computerized controller. This controller sends its signals to an electric-over-hydraulic manifold and corrects the reel rotation speed according to the tractor speed. This harvester can be mounted on most models of tractors from 35hp and up.

The operation of this harvester requires two people only, one to operate the tractor and the other to handle the boxes of berries on the rear-loading platform. These harvesters are available in single, double and triple head configurations. These machines have been proven to reduce the harvesting costs as much as 50% and are more efficient than hand raking for product recovery.

Hayden Manufacturing Company, Inc.

50 Carver Road, W. Wareham, Massachusetts

Tel: 1.800.294.0497 or 1.508.295.0497

Fax: 1.508.291.2577

E-mail: sales@haydenmfg.com

Website: www.cranberryantiques.com

For use on lowbush blueberries, agile and easy to operate, self-propelled by either 4 HP or 5-1/2 HP Honda Engine, clean picking. Darlington Blueberry Harvester.

DH Equipment, Inc.

Contact: Mario Hébert

31 Grand Rang S, Albanel, QC G8M 3L7

Tel.: 418.279.2006

E-mail: lesequipementsdh@hotmail.com

Website: www.equipementsdh.com (Products page)

DH Equipment has designed several machine models before arriving at a machine configured and optimized for wild blueberry picking.

Acadian Machine Works. Ltd.

Manufacturer in Prince Edward Island, Canada

17 Pine Tree Lane, Tignish, PE C0B 2B0, Canada

Phone: +1.902.882.2349

Website: www.acadianmachine.com

Walk behind harvester and tractor mounted harvester.

Pictou County Berry Limited

Blueberry Harvesting and Equipment Sales

Mike MacKay

RR 2 Trenton, NS

Tel.: 902.396.8364

E-mail: Mike@pictoucountyberryltd.com

Website: www.pictoucountyberryltd.com

Picking head mounted on a Grasshopper mower

No product guarantee or endorsement is implied, nor is discrimination intended against other sources.

Information in this publication is provided purely for educational purposes. No responsibility is assumed for any problems associated with the use of products or services mentioned. No endorsement of products or companies is intended, nor is criticism of unnamed products or companies implied.

© 2011, 2019

Call 800.287.0274 (in Maine), or 207.581.3188, for information on publications and program offerings from University of Maine Cooperative Extension, or visit extension.umaine.edu.

The University of Maine is an EEO/AA employer, and does not discriminate on the grounds of race, color, religion, sex, sexual orientation, transgender status, gender expression, national origin, citizenship status, age, disability, genetic information or veteran’s status in employment, education, and all other programs and activities. The following person has been designated to handle inquiries regarding non-discrimination policies: Director of Equal Opportunity, 101 Boudreau Hall, University of Maine, Orono, ME 04469-5754, 207.581.1226, TTY 711 (Maine Relay System).