Lesson 1: Sanitation and Food Safety for Cheesemakers

- Why Food Safety?

- Before Cleaning

- Cleaning and Sanitizing Steps

- TACT

- Precautions

- Cross-contamination

- Cleaning and Sanitizing the Cheese Vat

Why Food Safety?

Welcome to the Sanitation and Food Safety for Cheesemakers Training!

This training will cover some important points about cleaning and sanitizing in a cheesemaking facility. It will also review best practices of personal hygiene.

Proper sanitation, food safety, and personal hygiene practices are important for dairy farms since they can protect consumers from becoming ill and protect the cheesemakers’ business.

Before Cleaning

In any food processing facility, there are multiple food contact surfaces. A food contact surface is any surface that may enter into direct contact with the food. Examples are tables, shelves, scales, cutting boards, and utensils such as shovels, knives, etc.

Before you begin cleaning and sanitizing, you must remove any solids, dry or wet, present on the food contact surface.

For example, after a cheesemaking production run, all remaining curd pieces must be scraped off the vat, or otherwise removed, before you start the cleaning steps.

Remember: it is easier to remove solids before they dry out.

Cleaning and Sanitizing Steps

Do you know how many steps are needed to clean and sanitize a food contact surface properly? They are

- Pre-rinse

- Wash

- Rinse

- Sanitize

Before we describe each step, let’s review the differences between cleaning and sanitizing.

Cleaning involves the use of soap or detergent and warm water to remove all invisible soul form the service.

Sanitizing involves the use of a sanitizer to reduce microbes to a safe level on an already cleaned surface. Cleaning and sanitizing compounds should not be used interchangeably and should be used in the correct order: clean first and then sanitize.

Step One: Pre-rinse

Step One: Pre-rinse

Now let’s go through the steps together. The first step is pre-rinse.

In this step, you will wet the surface that is being cleaned to help loosen any soil or milk residue that may be present on the surface that was left after the initial step of removing the residual solids. This picture is a good example of how a food contact surface is properly pre-rinsed.

Step Two: Washing

Step Two: Washing

Washing is the second step in the process.

This step is performed with soap or detergent, warm water and some form of mechanical action, usually provided by brush, to remove food or soil that is on the surface. This picture demonstrates a cheesemaker properly washing a food contact surface.

Step Three: Rrinse

Step Three: Rrinse

The third step is to rinse the food contact surface.

This step washes off all the soap, as well as any remaining food particles, from the surface. After rinsing, the food contact surface should appear completely clean to the naked eye.

Step Four: Sanitize

Step Four: Sanitize

The final step is to sanitize the cleaned food contact surface. This step reduces the number of microbes to safe levels. It is important that all the soil and soap or detergent have been rinsed away. A sanitizer may not work as well if applied to a dirty or soapy surface. Some common chlorine-based sanitizers, like bleach, are inactivated by organic compounds like proteins and fats that are present in milk and curds. Remember, you must first clean and then sanitize.

TACT

Now that you know the four steps for cleaning and sanitizing (pre-rinse, wash, rinse, and sanitize), why is it important to have all four steps, and preform them in proper order?

Remember, it is NOT possible to properly sanitize if the surface is not cleaned first. It is also important to rinse the soap off the surface because soap or detergent can interfere with the efficacy of the sanitizer.

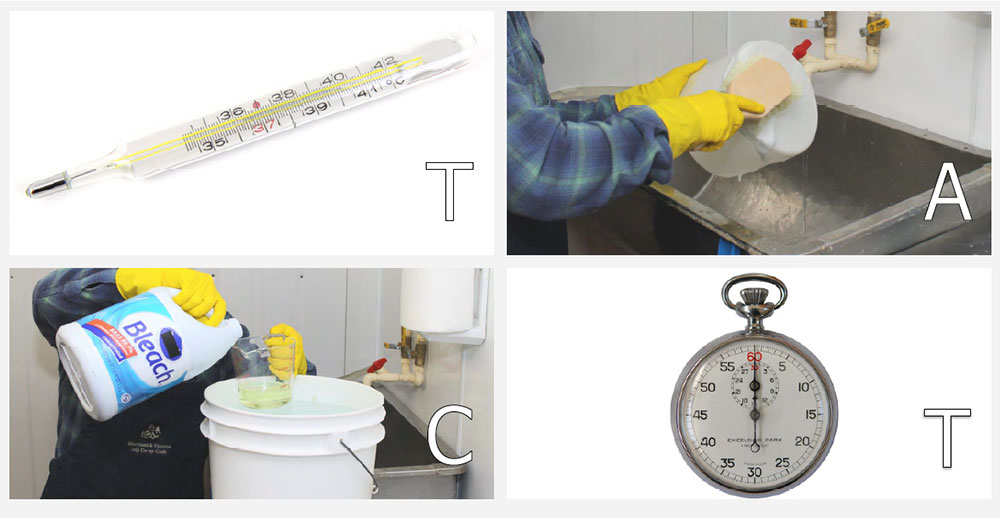

When it comes to the cleaning and sanitizing process, there are four elements that should be considered. These elements can be summarized by the acronym “TACT”. The first T stands for “Temperature,” the A for “Action,” the C for “Concentration,” and the second T for “Time.”

T = Temperature

T = Temperature

T is for temperature. Temperature is an important factor in the efficiency of cleaning and sanitizing. For example, if you use cold water in the pre-rinsing step, it might be harder to clean because some components will solidify. If the water is too hot, other compounds might “cook” and attach to the surface you are cleaning, also becoming harder to clean.

Temperature also affects sanitizer efficacy. Bleach works well in the temperature range of 75°F to 120°F.

If you mix or use bleach at high temperatures, the bleach will leave the solution as a gas, making the solution less effective against microbes. So, mixing bleach with cold or warm tap water is recommended.

If you are using another sanitizer, always read the label for proper instructions.

A = Action

A = Action

A is for action. Action is the mechanical force you apply to clean the surfaces. One example of action is scrubbing. The action you apply during the cleaning helps to physically remove food and bacteria that might be attached to the surfaces.

C = Concentration

C = Concentration

C is for concentration. Using an accurate concentration of soap or detergent and sanitizer is extremely important. If the concentration is too low, then it is not effective. However, if the concentration is too high, it violates federal regulations, can be wasteful and expensive and can harm people.

Some soaps and detergents can be applied directly to the surface to be cleaned. If you prepare your soap or detergent, always read the label for instructions and follow them.

The proper concentration of bleach for sanitizing surfaces is one tablespoon of bleach to one gallon of water to obtain a final concentration of 200 ppm. Remember to mix thoroughly before using.

If you use another sanitizer, always read the label for instructions and follow them.

T = Time

T = Time

T is for time. The amount of time that a surface is exposed to the sanitizing solution is very important for effective sanitation. Most sanitizers for food contact surfaces need a minimum for one minute contact time to kill the remaining microbes.

Also, sanitizer’s solutions lose their efficacy over time. It is important to make a fresh solution of bleach, at the correct concentration, at least once per day.

Precautions

When working with sanitizers, remember that they are chemicals and can be dangerous if not handled properly.

Be careful when mixing bleach or any other chemical at your establishment. For instance, when chlorine is accidentally mixed with acid solutions, chlorine gas can be generated, which is not only corrosive but can cause respiratory irritation to you or your workers. Also, do not mix ammonia solutions with bleach.

ALWAYS use proper concentration of chemicals since “more” is not necessarily better, and “less” is almost certainly less effective!

Finally, be sure to label all chemicals clearly and properly, and do not store them in food containers.

Cross-contamination

Cross-contamination: Ready-to-eat foods

Now let’s go over some important definitions related to food safety.

Ready-to-eat foods are usually products that are prepared (cooked, fermented, and acidified) in advance and can be eaten as sold. In other words, they don’t require any additional heating or preparation step and are eaten “as is.” Examples of ready-to-eat food include salads, deli meats, canned food, and of course, cheese.

Cross-contamination is the transfer of harmful substances or microbes (also known as contaminates) from something DIRTY to something CLEAN. On a dairy farm, we are concerned with the transfer of bacteria from unclean surfaces to food or food contact surfaces. One of the biggest concerns with cross contamination occurs when contaminants from a source outside the cheesemaking room are transferred, via the cheesemaker or employees, to the cheese or the food contact surfaces. Examples of cross contamination include handling or touching animals, followed by handling cheese with the same, unclean, hands.

Cross-contamination: Shoes or Boots

Cross-contamination: Shoes or Boots

The barn and other parts of a dairy farm are natural reservoirs of microbes. Try to minimize the transfer of microbes from those areas to the cheesemaking room.

One way for microbes to enter your cheesemaking room is on your shoes. Just by walking into the barn or outside, you will gather billions of microbes on the sole of your shoes. You must have a measure in place to minimize the carriage of those microbes inside the cheesemaking room.

- Use a boot bath with a sanitizer.

- Wear shoes that are used exclusively inside the cheesemaking room.

- Wash and sanitize your boots every time you re-enter the cheesemaking room.

A practical solution is to add a boot bath by placing a tray with sanitizer at the entrance door. Sanitizer in the tray should be made fresh every cheesemaking session and changed when visually dirty.

Having these boot baths in place when visitors tour the cheese making room is a good idea since they might bring microbes from other places.

If you prefer to wash your boots when entering, the same principle applies, as with cleaning equipment: remove gross contamination, use mechanical action, THEN use sanitizer.

Cross-contamination: Clothes

Cross-contamination: Clothes

Just like with your shoes, your clothes can carry microbes from the barn, the milking parlor, or the outside to the cheesemaking room.

To minimize the cross-contamination from your “street or barn” clothes, wear designated clothing, overalls, or aprons that are used exclusively inside the cheesemaking room. The best practice is to always change into clean clothes before entering the cheesemaking room for cheesemaking and also to use an apron.

You should avoid making cheese using the same clothes you used in the milking parlor. That is because animal’s excrement, and microbes from other sources, can be carried unnoticed on your clothes.

Cross-contamination: Cutting and Packing

Cross-contamination: Cutting and Packing

When cutting cheese for packaging, special care must be taken to avoid cross-contamination. The inner portions of the cheese that are isolated from the environment by the rind are exposed when cut. At this point, you are dealing with your final product, which is a ready-to-eat product. Any contamination transferred to the cheese at this step will likely reach your consumers. Proper cleaning and sanitizing all food-contact surfaces and utensils will reduce the risk of cross contamination. Food contact surfaces include but are not limited to: knives; cutting boards, cutting wires, vacuum packaging machine; etc. Remember it is important to use the four steps of cleaning and sanitizing for these food contact surfaces (1. pre-rinse; 2. wash; 3. rinse; 4. sanitize). You should also be wearing clean, untorn gloves at this step to minimize contamination of the cheese.

Cross-contamination: Transporting

Cross-contamination: Transporting

Transporting the cheese to sale locations offers another opportunity for cross contamination. Containers used for transportation, if not clean, can contaminate cheese. Another chance for contamination occurs when the same container is used for both cheese and raw products, such as meats or produce. Even frozen meat can still be a source of contamination. Therefore, fresh or frozen meat should not be placed in the same cooler as cheese. The ice used in the coolers should be made from potable water and frozen meat or other foods should not be used in places of ice.

Cleaning and Sanitizing the Cheese Vat

The correct way to clean and sanitize the vat is to follow the four steps for cleaning and sanitizing. Disassemble any fittings, screens, etc. that are on the vat and take them to a sink to be cleaned later. Remove any solids that may be present and then follow the same cleaning and sanitizing steps discussed before:

- Rinse the interior and the outside walls with warm water.

- Thoroughly brush all the inner walls, bottom, ridges, and exterior walls with soap. and warm water, being careful not to let the brush touch the floor.

- Rinse everything to remove the soap.

- Sanitize all areas that you brushed with a fresh, 200 ppm solution of bleach. This solution is prepared by adding one tablespoon of bleach to a gallon of water, if you use another sanitizer, please follow the preparation instructions listed on the container.

Follow the same steps for the fittings, screens, etc., using appropriately sized brushed to clean all interiors and exterior surfaces prior to sanitizing them. Reassemble as necessary. Your vat is now clean, sanitized and ready for use.

Frequency

All equipment, utensils, and food contact surfaces must be cleaned often. Some items require cleaning and sanitizing more frequently than others. Below are items that need to be cleaned and sanitized every time you make cheese:

All equipment, utensils, and food contact surfaces must be cleaned often. Some items require cleaning and sanitizing more frequently than others. Below are items that need to be cleaned and sanitized every time you make cheese:

- the vat,

- any utensils that you will use,

- knives and wire knives,

- hoops and hoops’ lids or covers, and

- other equipment that has direct contact with the milk or curds, like pasteurizers, milk cans, agitation blades, etc.

If utensils cannot be stored in a way that avoids cross- contamination from non-food- contact surfaces. They need to cleaned and sanitized before they come in contact with the milk or curds every time. Some examples are:

- Thermometers

- Knives or another utensil to check coagulation

Non-food-contact surfaces should receive regular cleaning, depending on use. You should develop a schedule for cleaning each of the following items:

- Floors

- Walls

- Shelves

- Sinks

- Other non-food-contact surfaces you might have

DO NOT use the same brush to clean the floors, walls, etc., for cleaning the food contact surfaces.